stever_sl

ACCESS: Confidential

- Joined

- 31 August 2010

- Messages

- 86

- Reaction score

- 456

Back in the late 1980s or early 1990s (my hard drive failed a couple of months ago and I haven't been able to reconstruct all of my records) I was working in the general area of AV-8B, and specifically its vulnerability to combat damage. The USMC came to us and asked what would be the smallest, hardest (in a vulnerability sense) AV-8B variant that was technically feasible by the year 2000. The word "smallest" became very important, as it turned out, because in order to make the Harrier any less vulnerable we knew that we'd have to add a significant amount of weight, which wouldn't be possible with the current Pegasus engine, and we couldn't use a new engine because that would add billions of development dollars that the Marines simply didn't have, so if any way could be found to reduce the size of the aircraft, we might find some offsetting weight savings.

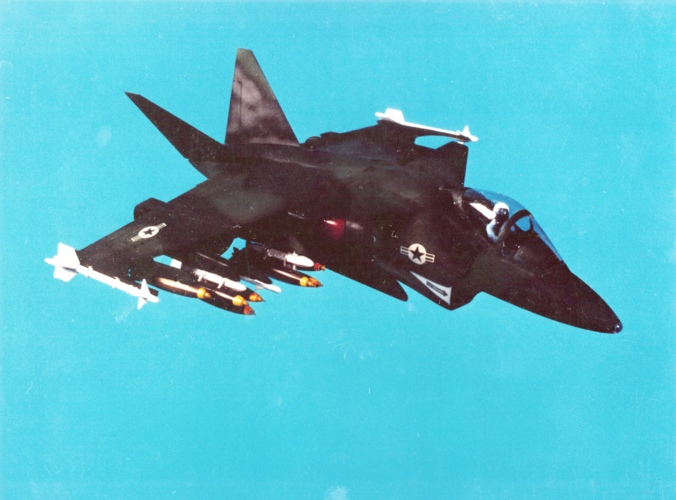

We had just finished doing the AV-8B vulnerability analyses by hand, which involved looking at a lot of drawings of the AV-8B and its subsystems, and it occurred to me that the only major thing in the entire aft fuselage was some sort of electrical panel (relays maybe? it was a long time ago) and it (they?) could easily be relocated, leaving an empty space whose only purpose was to provide structural support for the tail surfaces. Cut all of that away, fair off the back end, move the horizontal tails in front of the wings to become canards, borrow new vertical tails from F/A-18s, and an interesting-looking canard-delta(ish) configuration emerged. We knew we could get more engine thrust if we had longer inlet ducts, so those got pushed forward which gave us the space we needed to mount the canards. At the time, the Marines were pretty vocal about not liking the AV-8B's 25mm gun, so that got tossed and replaced with the 4-barrel version of the A-10's 30mm gun. There wasn't room for it internally so it went under the belly, but that got in the way of the nose landing gear, and the additional loss of the location for the main landing gear led to a beefing up of the wing structure so that the outriggers became essentially main landing gear housings. I built a model to show the concept, our manager took it on the road, it generated enough interest to do more work on the configuration, but ultimately it didn't go forward. I still have the model on my shelf, and the company took this one photo to document the idea. Just thought any Harrier variant geeks might get a kick out of it.

We had just finished doing the AV-8B vulnerability analyses by hand, which involved looking at a lot of drawings of the AV-8B and its subsystems, and it occurred to me that the only major thing in the entire aft fuselage was some sort of electrical panel (relays maybe? it was a long time ago) and it (they?) could easily be relocated, leaving an empty space whose only purpose was to provide structural support for the tail surfaces. Cut all of that away, fair off the back end, move the horizontal tails in front of the wings to become canards, borrow new vertical tails from F/A-18s, and an interesting-looking canard-delta(ish) configuration emerged. We knew we could get more engine thrust if we had longer inlet ducts, so those got pushed forward which gave us the space we needed to mount the canards. At the time, the Marines were pretty vocal about not liking the AV-8B's 25mm gun, so that got tossed and replaced with the 4-barrel version of the A-10's 30mm gun. There wasn't room for it internally so it went under the belly, but that got in the way of the nose landing gear, and the additional loss of the location for the main landing gear led to a beefing up of the wing structure so that the outriggers became essentially main landing gear housings. I built a model to show the concept, our manager took it on the road, it generated enough interest to do more work on the configuration, but ultimately it didn't go forward. I still have the model on my shelf, and the company took this one photo to document the idea. Just thought any Harrier variant geeks might get a kick out of it.