You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Northrop N-63 VTOL

- Thread starter allysonca

- Start date

- Joined

- 27 December 2005

- Messages

- 16,888

- Reaction score

- 21,589

I love your work.

Do you think there is a danger of your newly built models being passed off as original vintage models? Or are the materials used different enough to be identified? Its a bit of a blurry line given you actually did build models back in the past as official manufacturer commissions.

Do you think there is a danger of your newly built models being passed off as original vintage models? Or are the materials used different enough to be identified? Its a bit of a blurry line given you actually did build models back in the past as official manufacturer commissions.

Last edited:

- Joined

- 18 June 2009

- Messages

- 1,348

- Reaction score

- 2,256

Allyson,

What materials are you working in? Looks like wood inside the intakes; what kind? Hopefully you have some earlier process pictures. I have a tube of 3M Acryl-Green Spot Putty on my workbench too. For some reason, the other guys in my shop liked Acryl-Red which I thought was only good for bleeding through any light colored paint.

Richard

What materials are you working in? Looks like wood inside the intakes; what kind? Hopefully you have some earlier process pictures. I have a tube of 3M Acryl-Green Spot Putty on my workbench too. For some reason, the other guys in my shop liked Acryl-Red which I thought was only good for bleeding through any light colored paint.

Richard

- Joined

- 11 March 2011

- Messages

- 295

- Reaction score

- 1,084

Well, I AM a maker of models for Northrop, in the past. I produced the 1/72 YF-23. B2 and the Tucanos, as well as an assortment of F-5's and F-20, 's so you can say that I am an authorized maker no? As to fear of counterfeiting, no as in all of my years of manufacturing or colling there has never been anything made that I carve. I do use the same techniques and finishes as in-house and DO keep in mind that many a manufacturer outsourced work to many makers over the years.I love your work.

Do you think there is a danger of your newly built models being passed off as original vintage models? Or are the materials used different enough to be identified? Its a bit of a blurry line given you actually did build models back in the past as official manufacturer commissions.

- Joined

- 11 March 2011

- Messages

- 295

- Reaction score

- 1,084

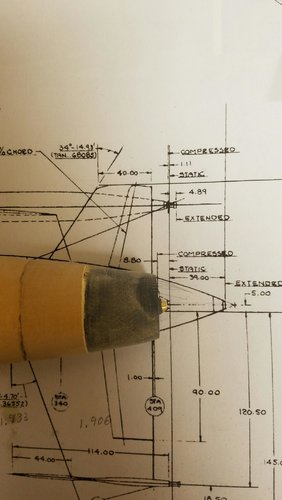

Hi Richard, We carve in Jelutong wood, and the N-65 also has a lot of hand-turned brass, acrylic plastics, and any other stable materials to complete the model. There are even some BIC pen springs that allow the tail cone to retract and extend when sitting on its legs. All models are primed and finished in Lacquers (I have a local paint shop that has formulas back to the 1920's) and also like shooting in Vallejo Air paints for a lot of the work I do as well. I like to use Evercoat for fill and shaping as it is a great two part putty that cures fast. I'll post some other pictures of the work we do.Allyson,

What materials are you working in? Looks like wood inside the intakes; what kind? Hopefully, you have some earlier process pictures. I have a tube of 3M Acryl-Green Spot Putty on my workbench too. For some reason, the other guys in my shop liked Acryl-Red which I thought was only good for bleeding through any light colored paint.

Richard

The spot putty is just an easy quick fill for light pinholes and has never presented an issue, but it is not the go to over the Evercoat. I like to use the quick cure Evercoat and can touch up over the work easily. I've been collecting and refinishing factory models for over 50 years, been friends with many of the old companies and makers and use similar styles and techniques when restoring or creating new works.

- Joined

- 11 March 2011

- Messages

- 295

- Reaction score

- 1,084

Hi Richard, We carve in Jelutong wood, and the N-65 also has a lot of hand-turned brass, acrylic plastics, and any other stable materials to complete the model. There are even some BIC pen springs that allow the tail cone to retract and extend when sitting on its legs. All models are primed and finished in Lacquers (I have a local paint shop that has formulas back to the 1920's) and also like shooting in Vallejo Air paints for a lot of the work I do as well. I like to use Evercoat for fill and shaping as it is a great two part putty that cures fast. I'll post some other pictures of the work we do.Allyson,

What materials are you working in? Looks like wood inside the intakes; what kind? Hopefully, you have some earlier process pictures. I have a tube of 3M Acryl-Green Spot Putty on my workbench too. For some reason, the other guys in my shop liked Acryl-Red which I thought was only good for bleeding through any light colored paint.

Richard

The spot putty is just an easy quick fill for light pinholes and has never presented an issue, but it is not the go to over the Evercoat. I like to use the quick cure Evercoat and can touch up over the work easily. I've been collecting and refinishing factory models for over 50 years, been friends with many of the old companies and makers and use similar styles and techniques when restoring or creating new works.

Attachments

- Joined

- 18 June 2009

- Messages

- 1,348

- Reaction score

- 2,256

Allyson,

Very nice work. I've heard of jelutong for years, but never came across any and always found basswood easy to find and work. Most of the time, I use Renshape since it can be worked as easily as basswood and has no grain, is strong in thin sections, and finishes quickly with a couple of coats of lacquer primer. Are you using the flowable Evercoat as your wood filler?

In your last picture, I see the bow of a boat. Is that another project or hobby?

Richard

Very nice work. I've heard of jelutong for years, but never came across any and always found basswood easy to find and work. Most of the time, I use Renshape since it can be worked as easily as basswood and has no grain, is strong in thin sections, and finishes quickly with a couple of coats of lacquer primer. Are you using the flowable Evercoat as your wood filler?

In your last picture, I see the bow of a boat. Is that another project or hobby?

Richard

- Joined

- 11 March 2011

- Messages

- 295

- Reaction score

- 1,084

I've thought about Renshape but all of the "old school" models were always wood, so that is my choice. Evercoat is a great stable shaper and filler and I highly recommend it. The boat was a project of the owner of Micro West, Paul Williams who sadly passed 3 months ago. I used his tools and spray booth. We were friends for over 50 years and met him when he worked for my friend Al Parker when he was a partner at Marketing Aids.Allyson,

Very nice work. I've heard of jelutong for years, but never came across any and always found basswood easy to find and work. Most of the time, I use Renshape since it can be worked as easily as basswood and has no grain, is strong in thin sections, and finishes quickly with a couple of coats of lacquer primer. Are you using the flowable Evercoat as your wood filler?

In your last picture, I see the bow of a boat. Is that another project or hobby?

Richard

- Joined

- 18 June 2009

- Messages

- 1,348

- Reaction score

- 2,256

My models are a bit larger and can wind up going through temperature changes and rough handling, so there is a minimum of body filler used and most shapes are blocked out with Renshape. Most old wood models I've seen have cracks in the finish caused by the wood underneath breathing over the years. Renshape isn't affected by temperature, humidity, or solvents and takes paint very well. I've included a couple of pictures of a fiberglass model I had to modify and all of the pink planar surfaces are Ren with filler used only for gaps or fillets. The nose ball was Ren already primed.

BTW, the customer didn't have drawings and couldn't get any in the short time frame. I was given screen captures of a digital model and spent a fair amount of time googling to find pictures of the real thing. Building only from photos happens a lot. Even inside a company, drawings can be impossible to get unless you have a charge number and get a bunch of authorizing signatures.

BTW, the customer didn't have drawings and couldn't get any in the short time frame. I was given screen captures of a digital model and spent a fair amount of time googling to find pictures of the real thing. Building only from photos happens a lot. Even inside a company, drawings can be impossible to get unless you have a charge number and get a bunch of authorizing signatures.

Attachments

- Joined

- 11 March 2011

- Messages

- 295

- Reaction score

- 1,084

WOW REALLY nice work. 10th scale is wonderful and sadly I've only had room for a few. Finish work is outstanding. Curious, was there a factory premade model as the base for the conversion? Where is your shop? I've had so many models that show the construction stations where the wood shrunk, but it does give character. Many of the wood models I've collected are very stable but depending on the maker there can be issues, but for the most part in a temperature controlled room they are less prone to any shrinkage.......but on occasion..................

- Joined

- 18 June 2009

- Messages

- 1,348

- Reaction score

- 2,256

It was a fiberglass model that the customer already had and they had been referred to me by a friend. Naturally, they needed it quick for an overseas show. That is the deck behind my house in the picture. My shop is part in my home and the rest in a large RV garage that was half the reason I bought this house. The heavy dust making machinery is out in the garage and smaller machine and hand tool work is done in the house. I had previously worked for industrial designers and in a couple of corporate model shops and am now a vendor. What do you do for a shop?

Like you say, wood shrinks. As much as I like working with wood, if I am doing something that I don't want to have coming back to me because witness lines or cracks have spoiled the finish, I don't use wood on anything that is going to show and instead use Renshape or fiberglass with high temperature tolerant epoxy. Airshows and displays can get very hot in the sun. Renshape is very stable and excellent about not showing joints between itself or other materials. I also use urethane castings from RTV silicone molds that I make and shoot.

The only exposed wood I use is in my flying models where balsa and spruce have always been the materials to use and the airframes are covered in plastic film, so their ability to maintain a finish isn't such a big deal. I don't worry that much about the finish on my flying models since my real enjoyment is in the flying. I will take a rough looking good flyer any day over a pristine hanger queen.

Like you say, wood shrinks. As much as I like working with wood, if I am doing something that I don't want to have coming back to me because witness lines or cracks have spoiled the finish, I don't use wood on anything that is going to show and instead use Renshape or fiberglass with high temperature tolerant epoxy. Airshows and displays can get very hot in the sun. Renshape is very stable and excellent about not showing joints between itself or other materials. I also use urethane castings from RTV silicone molds that I make and shoot.

The only exposed wood I use is in my flying models where balsa and spruce have always been the materials to use and the airframes are covered in plastic film, so their ability to maintain a finish isn't such a big deal. I don't worry that much about the finish on my flying models since my real enjoyment is in the flying. I will take a rough looking good flyer any day over a pristine hanger queen.

- Joined

- 11 March 2011

- Messages

- 295

- Reaction score

- 1,084

We use my friend Steve's garage/shop to do restorations and to paint the larger models. He is the brother of the late Paul Williams of Micro West. I can handle up to 1/32 here in my studio and most of the dusty work is at Steves. We too use resins, and we get ours from BJB out here, and the best silicon mold materials from Smooth On. Most, if not all of our work is usually one-if-a-kinds and a lot of restorations for collectors and the occasional heli for Sikorsky pops thru. Our Jelutong is quite stable and gives us the best sharp trailing edges. We use a little trick I discovered when carving foams that consists of soaking thin Cyano into the wood to add strength. Be surprised how robust this can make the materials.

Similar threads

-

Northrop N-63 Convoy Fighter: Naval VTOL Turboprop Tailsitter Project of 1950

- Started by jzichek

- Replies: 11

-

-

-

Northrop N-251 supersonic VTOL interceptor concept

- Started by circle-5

- Replies: 5

-

Unknown USAF supersonic VTOL Fighter competition from 1959

- Started by nugo

- Replies: 16