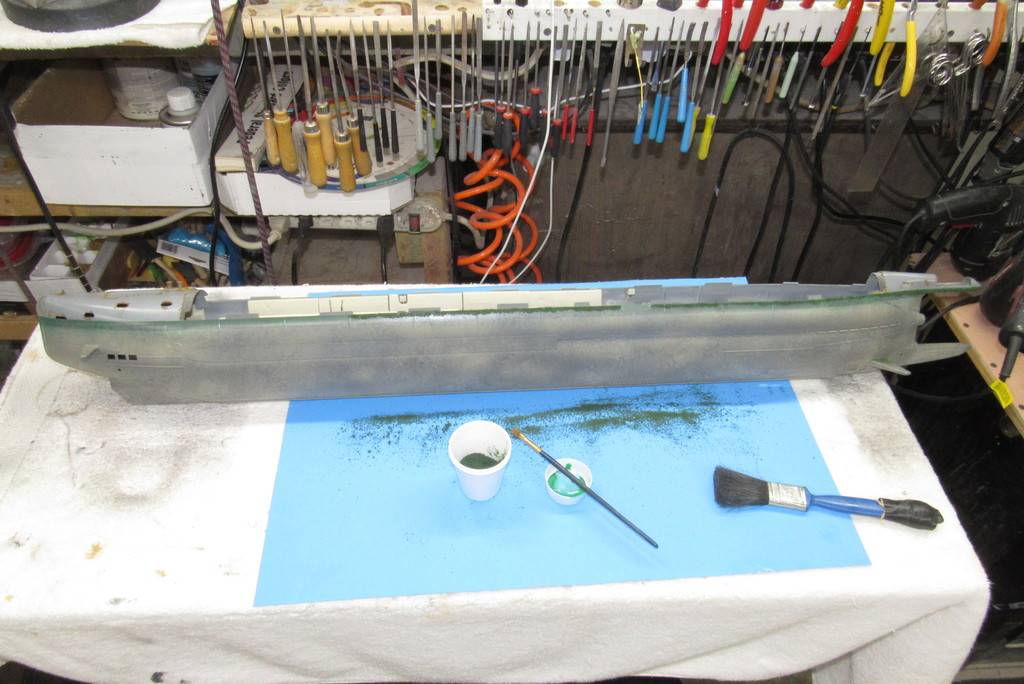

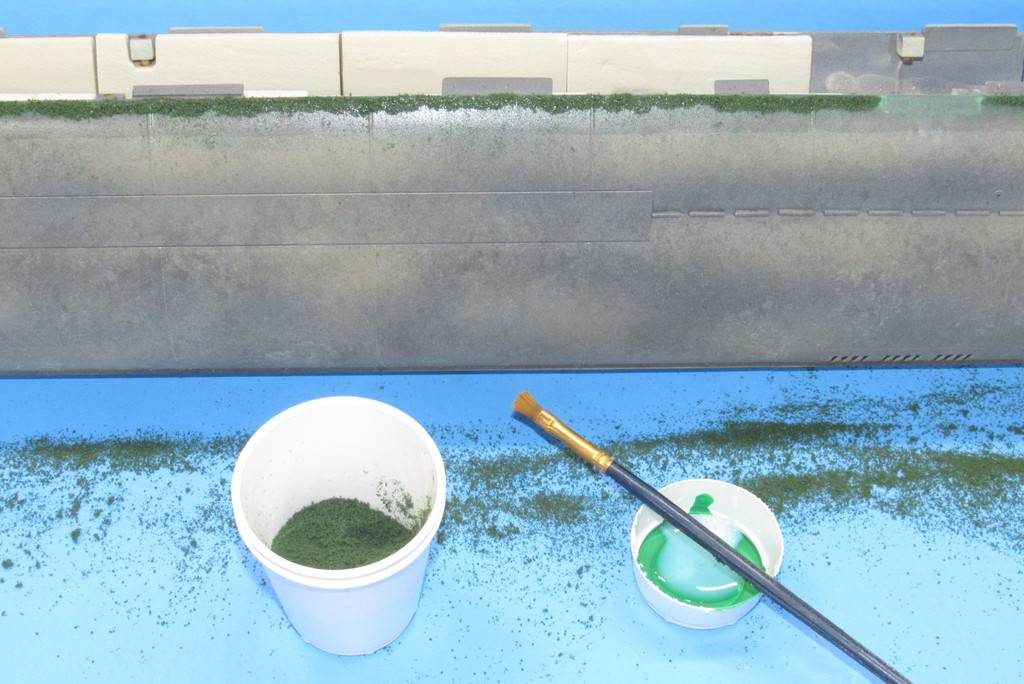

The larger sized submarines, and by that, I mean just about any watercraft of 1/48th or larger, are big enough to realistically employ model railroad green 'fine turf' as a stand in for the waterline 'grass' often observed on boats either tied up to a pier, or recently left standing on keel blocks in dry-dock. The 1/35 Bronco Type-23 model was a perfect candidate for this treatment.

The trick is simple: brush on a slow-dry/cure adhesive at the waterline – water soluble (but waterproof after drying) acrylic 'medium' is the adhesive of choice here. Before the glue dries you simply sprinkle on railroad turf and pat it down every so lightly to embed most of it into the glue. Leaving the work alone til the glue dries/cures hard.

The majority of the rail-road turf will fall way as its laid down and patted into place, so it's a good idea to do the work over a piece of cardboard that make reclaiming of the turf that falls away an easy matter.

Note that the majority of the break between lower and upper hull halves was made at the waterline. I only had to take care of the bow and stern sections when laying down the glue as the central portion of the lower hull had its break edge at the waterline – no way to screw up with the brush there!

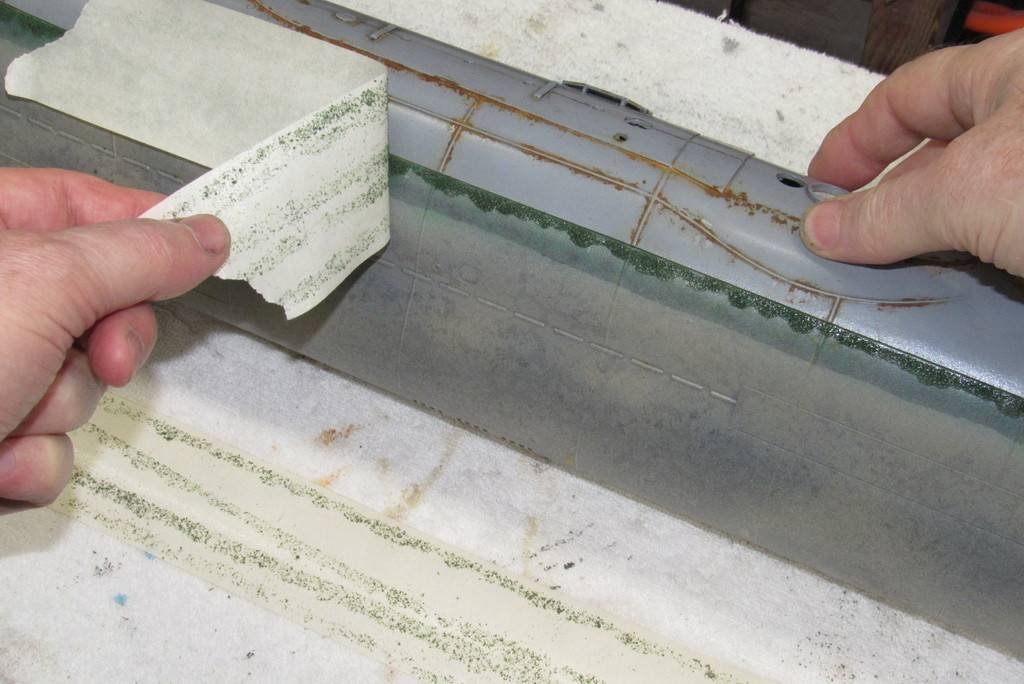

Once the glue had dried masking tape was used to pull away any turf not secured enough to keep it from flying away during the clear-coating lay-down – which would ruin the effort. The model was then ready for any touch-up painting and given a final well flattened clear-coat to lock down all paint and weathering agents and to give the display a uniform sheen.

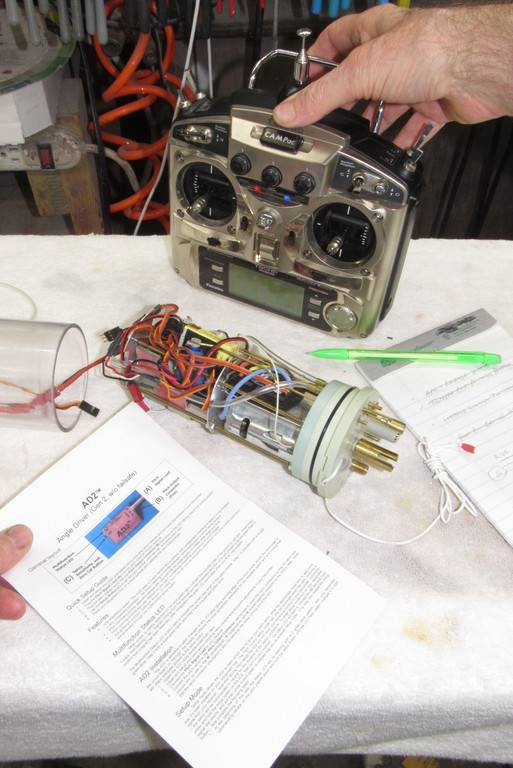

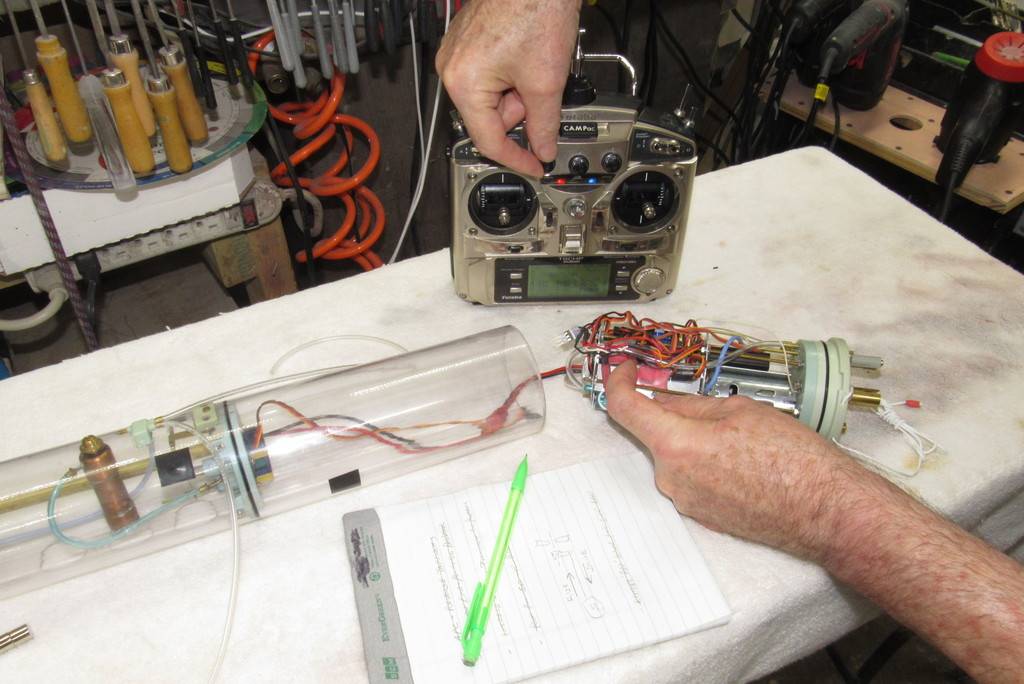

Almost done with the Ray Mason Disney NAUTILUS Jake has assembled and painted. It's now in my horrible custody for final checks, dial-in, and trimming before we can declare this thing certified and ready to cruise the Red Clay Resort swimming pool looking to ram ships found to be in the service of that, 'accursed nation' (I'm looking at you, Casey!)

Here I'm putting on the final touches to free up the propeller gimbal mechanism. As the Disney NAUTILUS had no practical planes to control pitch I've elected to vary the propeller thrust line about the pitch axis to effect pitch angle changes and maintenance – needed to make this otherwise incredible submarine work in a credible manner.

Jake was here yesterday with the painted model – and he did a wonderful job too, simply beautiful and so gracefully capturing the look of the movies miniatures and full-scale sets. Trouble was – though we planned to have it in my test tank for final trimming, we kept encountering gremlins with the electronics.

After a half-day of sleuthing, I finally narrowed the search down to an intermittently working battery eliminator circuit (BEC) – it worked sometimes, sometimes it worked half-ass, and other times it would not work at all. Replaced that POS problem-child with another and all problems went away. It was not until this morning I could put the NAUTLUS in the water and set the end-points for the throttle.

While at it I reduced the sensitivity of the angle keeping device – which controls the servo that works to pitch the propeller shaft axis about the pitch plane – to keep the propeller from jumping about owing to motor and running gear vibrations.

This morning, in the test tank, with everything in the water, I got the hoped for damping effect that attenuated most of the vibration sources; this greatly reduced the inevitable twitching produced by the angle keeper in response to system motor and servo operation.