First announced some months ago, the cross-over exhaust system developed for the Merlin T.M.L.* power plant by Rolls-Royce, Ltd., is now entering B.O.A.C. service—in particular, all four engines of the Argonaut Atalanta, in which H.M. The Queen recently flew to Kenya and back, were fitted with it.

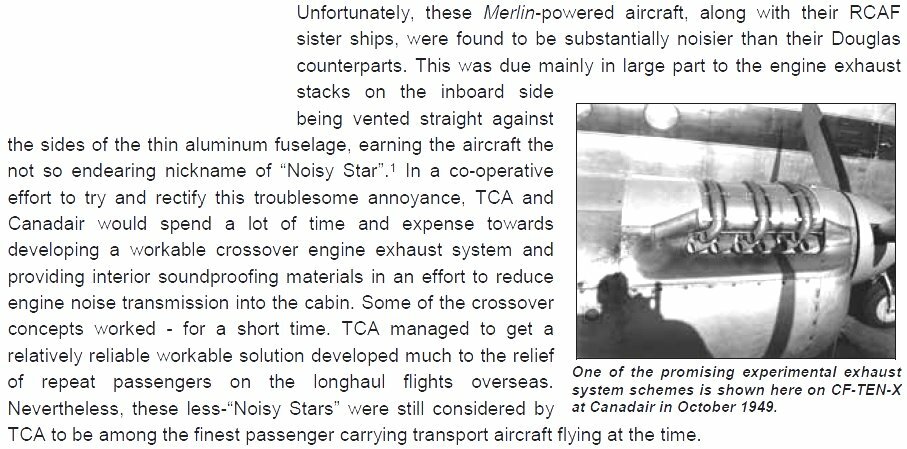

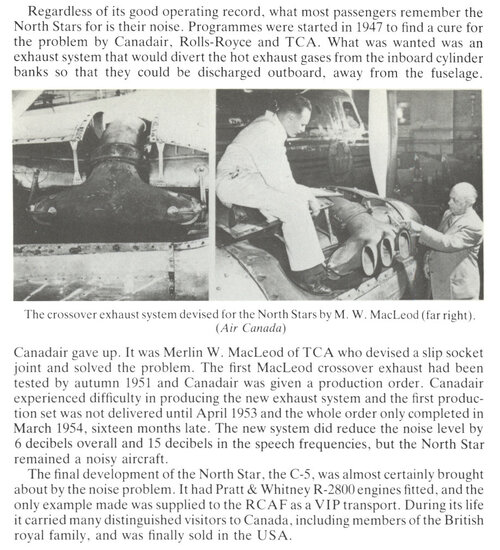

Both Rolls-Royce and B.O.A.C. have long appreciated the fact that the Argonaut (Canadair DC-4M) could well be made a quieter aircraft; to do so, however, and lose nothing in the way of performance, was a much greater problem, and Rolls-Royce have spent a considerable period in finding the best solution. It must therefore be with some gratification that they can now announce the development of this new exhaust system which, while effecting a marked reduction in noise level, actually improves performance.

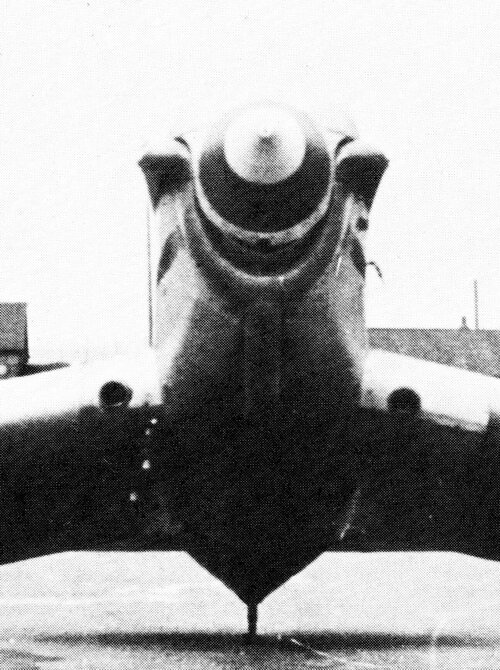

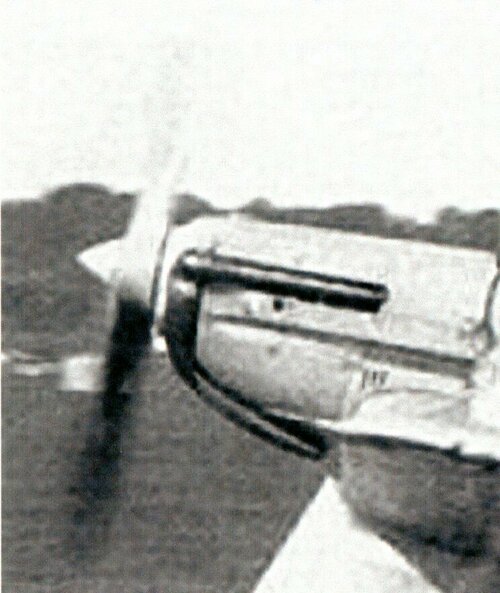

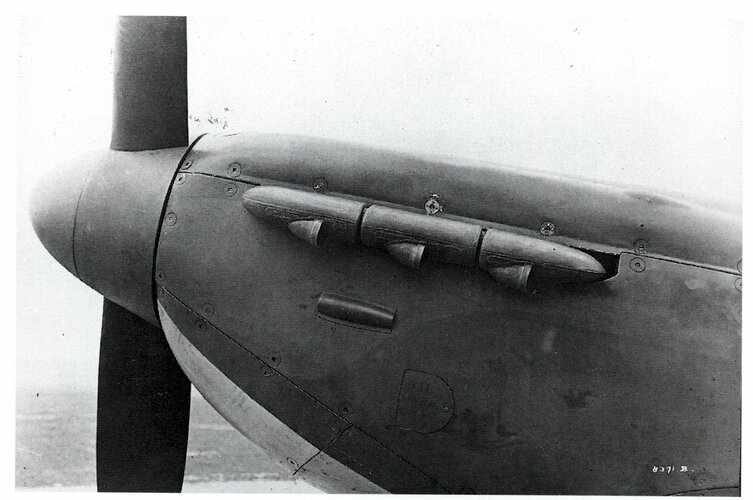

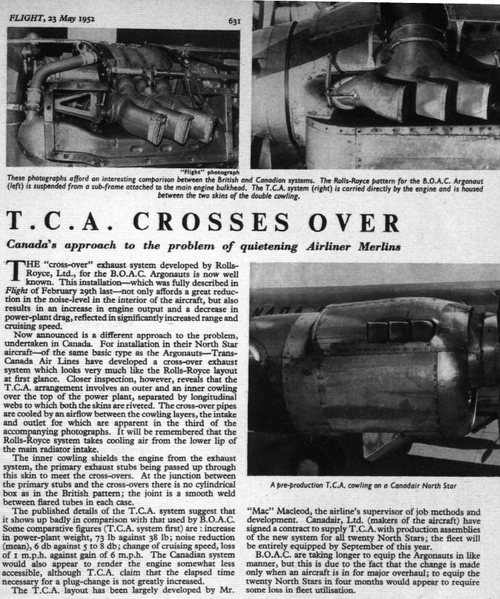

B.O.A.C. recently afforded us the opportunity of examining this new power plant —redesignated Merlin T.M.O.— at London Airport, and the accompanying photographs show the system to good advantage.

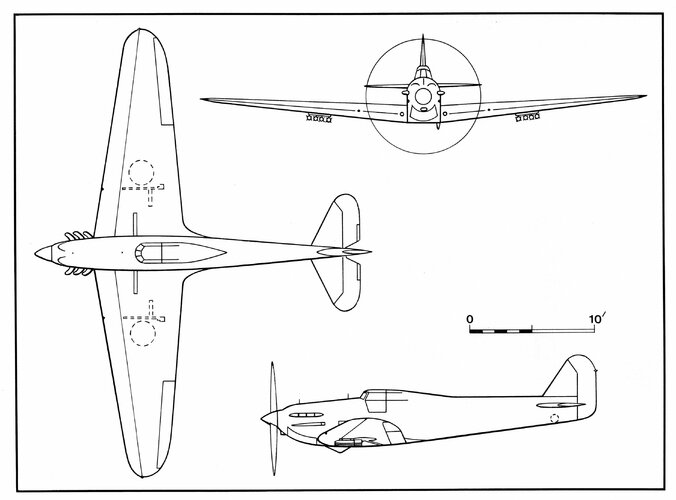

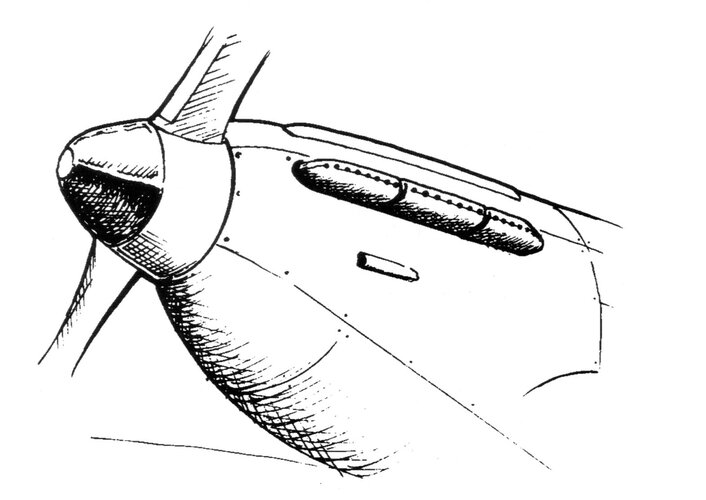

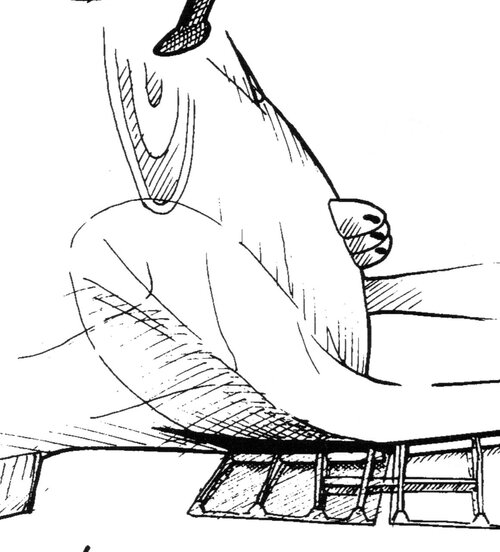

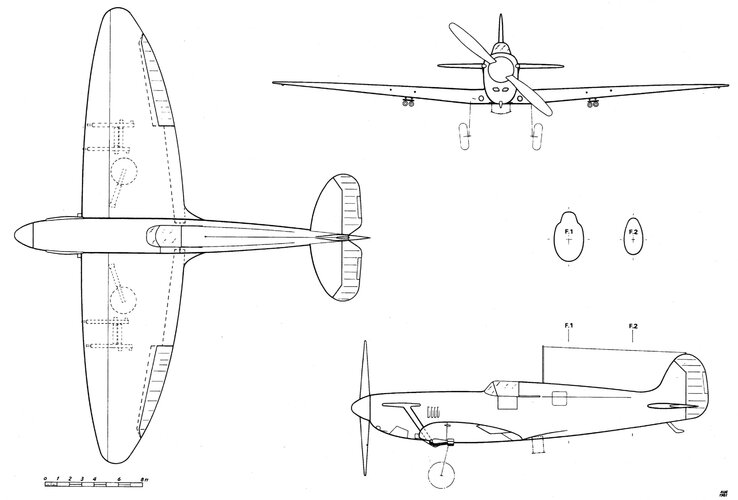

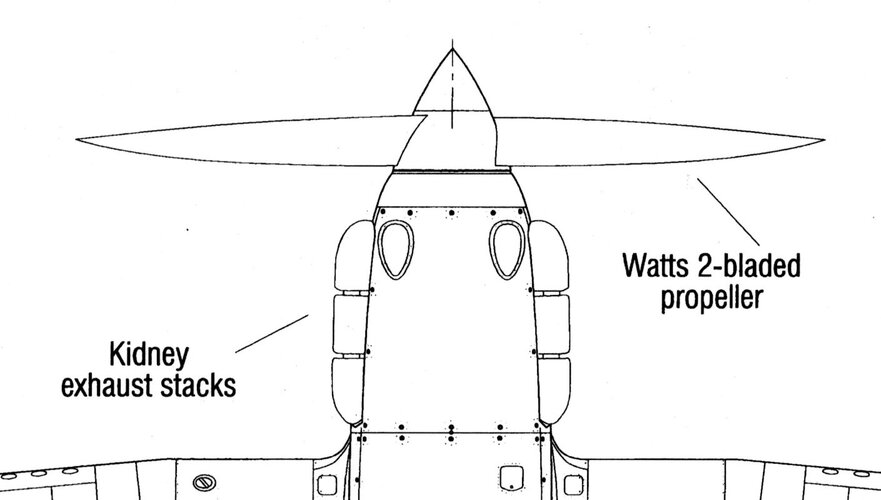

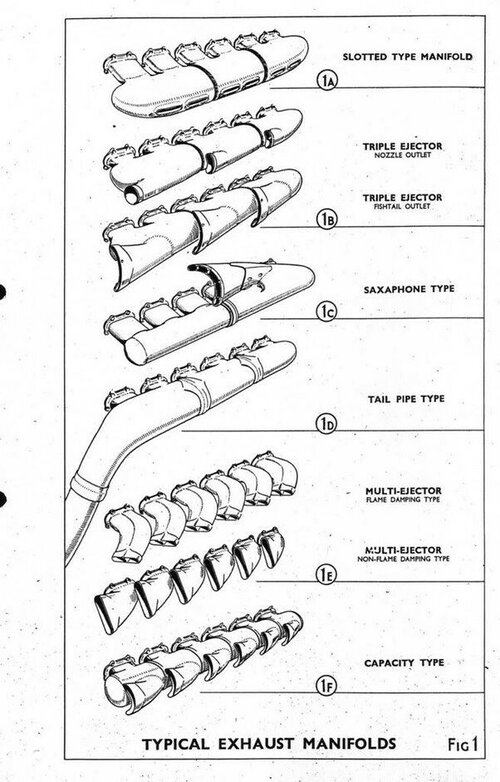

Beside each cylinder bank, and suspended from a sub-frame off the main bulkhead, is a cylindrical manifold into which the adjacent cylinders exhaust via ball-jointed stubs. The two manifolds of each power plant are symmetrically connected by three stainless-steel pipes which carry the exhaust from the inner bank of each engine over to the outer manifold; final release to atmosphere is made through three stubs ejecting on the outer side of each cowling.

The manifolds and primary exhaust stubs are made of Inconel, and are designed to be free from stresses arising from engine vibration, while affording the clearest possible gas path. The system is cooled by air drawn in at an intake placed centrally on the lower lip of the main radiator intake.

This position receives the full benefit of both airscrew slipstream and ram air, and results in effective cooling under all conditions. From the new intake the flow is divided, one stream cooling the primary stubs and the adjacent ignition harnesses, while the other passes over the connecting pipes; both exhaust from herringbone-shaped louvres above the cowling.

The cross-over modification also involves replacement of the existing main coolant radiator by a unit made entirely of light alloy, while a new circular brass oil-cooler is also specified. The modified power plant is interchangeable port and starboard by fitting the appropriate ejector-stubs to the outer side of the engine, and the correctly handed blanking-plate on the fuselage side. The new exhaust system is completely interchangeable with the original system, the only parts affected being the valve rocker-box covers, ignition harness, and fire extinguishers, all of which are supplied by Rolls-Royce in the modification kit.

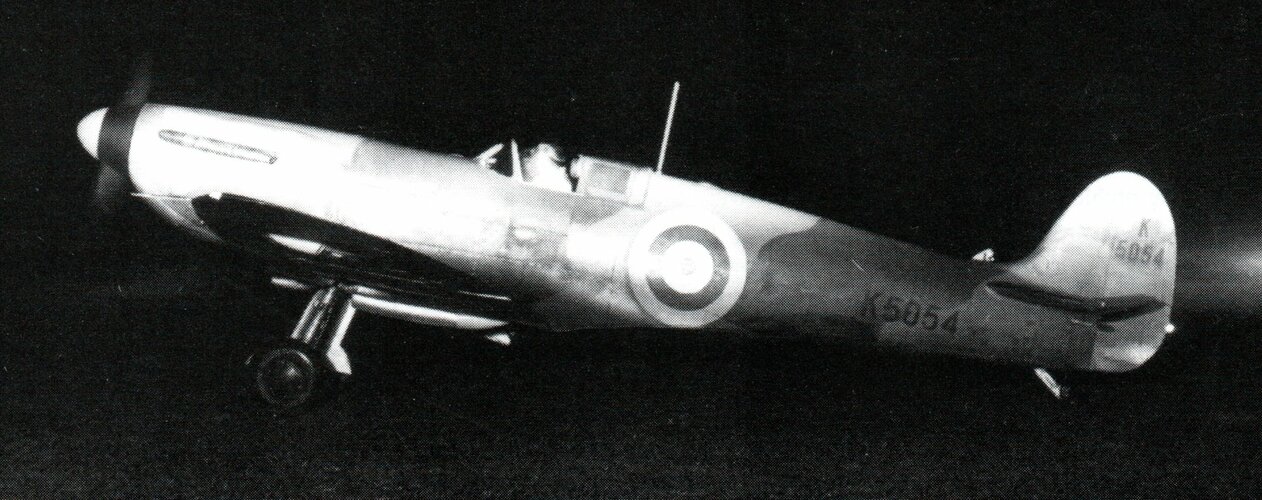

The reduction in noise is achieved both by exhausting away from the fuselage—exhaust flow, incidentally, is entirely above the wing—and also by the mutual cancellation of many of the harmonic constituents of the noise spectrum. Throughout, close attention has been paid to providing unrestricted gas-flow, and to reducing installation-drag; the result has been a back-pressure reduction giving an additional 38 b.h.p. at maximum power per engine in comparison with the original Merlin T.M.L., while the cleaner installation results in a gain in T.A.S. of some 5 kt over the range of cruising speeds. The factors combine to increase the specific air range of the Argonaut by some 4 per cent, and to reduce the noise level by between 5 and 8 decibels; the greatest silencing effect is obtained in the higher frequencies, which are those most affecting passenger comfort.

The penalties involved appear to be negligible; the [could not locate next page]

* "T.M." denotes "Transport Merlin" and is followed by a serial letter.