X-43 Design Lead

ACCESS: Restricted

- Joined

- 23 October 2023

- Messages

- 17

- Reaction score

- 112

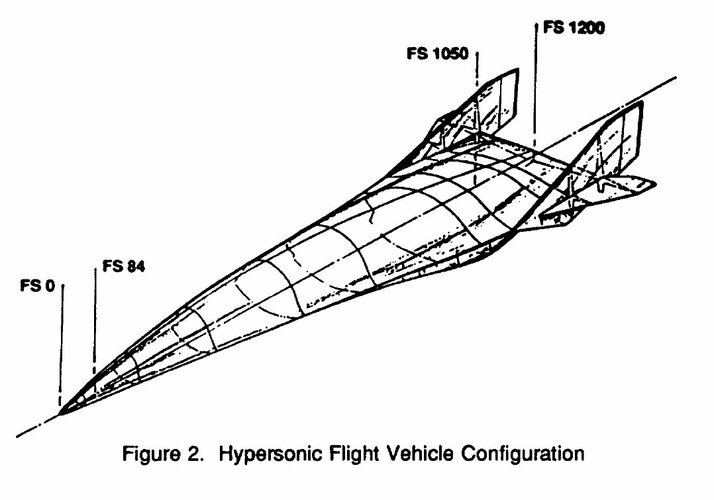

My name is Carl F Tarricone, in 1995 I led the Design and system integration team for X-43 Hyper-x. We accomplished that design in 8 weeks. Once we positioned the bulkheads we then started placing the necessary flight systems where they needed to be. The GASL engine module was placed first. A 3-D model of the vehicle was developed using Unigraphics 9 and then upgraded to Unigraphics 13 for solids modeling and updating purposes.

George Orton was Program Manager in St Louis, Ed Eiswirth was Chief Engineer and I was in charge of Design and System Integration.

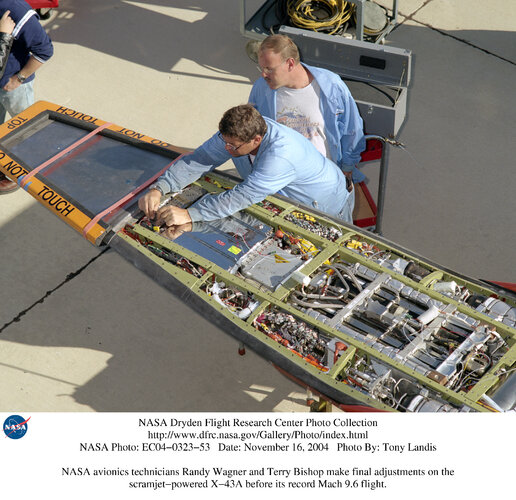

Our two daunting challenges were heat and physical space to place the systems.

NASA wanted over 350 channels of telemetry and a variety of sensors covering the vehicle.

The tubing and wiring needed was ridiculous and was near impossible to model.

We came up with two unique approaches to vehicle construction, first, instead of applying numerous Thermal Protection System (TPS) tiles to the outer surface, we introduced the idea of applying large pieces and then machining the foam ceramic in a large NC controlled machine.

The other unique feature was how we gained access inside the vehicle for service and flight prep. We developed threaded plugs made from the AETB (Alumina Enhanced Thermal Barrier) developed by McDonnell Douglas Huntington Beach.

Those two design features were somehow leaked to the Microcraft Team before the contract to build the vehicle was awarded. The system arrangement that was built is pretty much what was built.

Coincidentally, I was also assigned to Copper Canyon around 1983 and another proprietary program at the same time.

I was actually assigned to Hyper-x as a way to fail because of the extremely tight schedule and a clear reason to discharge me.

I had one hell of a team and there were only about 8-10 of us and worked long hours. We sent the finished CAD model to NASA 15 minutes before deadline.

Carl F Tarricone

Boeing Phantom Works (Retired 2009)

McDonnell Douglas Phantom Works 1983-2009)

I hope this sheds some light on this monumental vehicle in light of the current interest in Hypersonic Flight Regime.

George Orton was Program Manager in St Louis, Ed Eiswirth was Chief Engineer and I was in charge of Design and System Integration.

Our two daunting challenges were heat and physical space to place the systems.

NASA wanted over 350 channels of telemetry and a variety of sensors covering the vehicle.

The tubing and wiring needed was ridiculous and was near impossible to model.

We came up with two unique approaches to vehicle construction, first, instead of applying numerous Thermal Protection System (TPS) tiles to the outer surface, we introduced the idea of applying large pieces and then machining the foam ceramic in a large NC controlled machine.

The other unique feature was how we gained access inside the vehicle for service and flight prep. We developed threaded plugs made from the AETB (Alumina Enhanced Thermal Barrier) developed by McDonnell Douglas Huntington Beach.

Those two design features were somehow leaked to the Microcraft Team before the contract to build the vehicle was awarded. The system arrangement that was built is pretty much what was built.

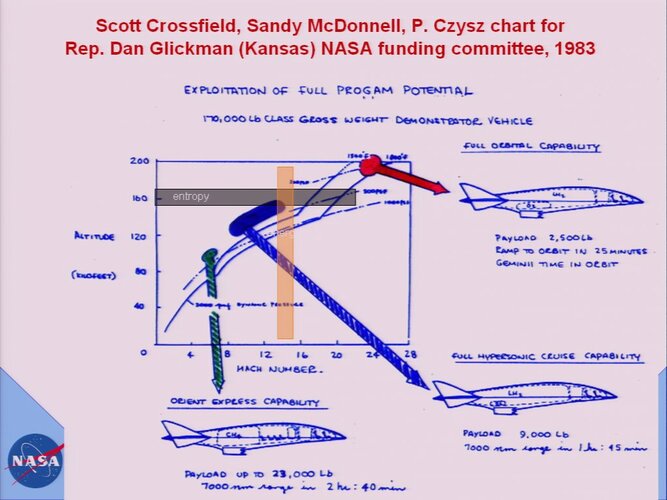

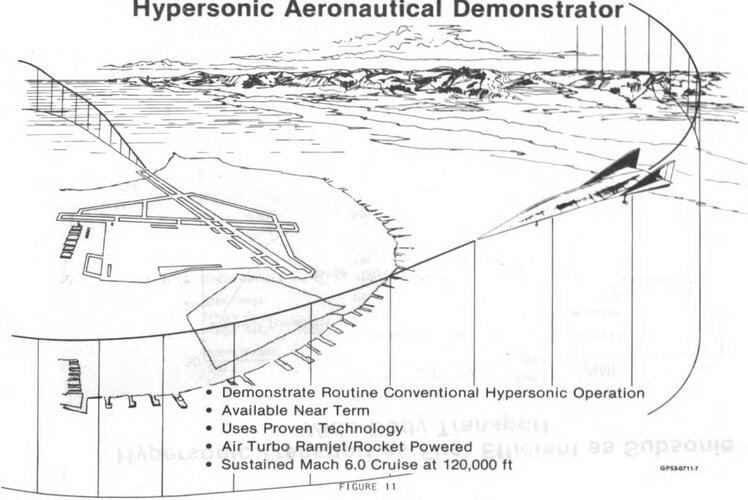

Coincidentally, I was also assigned to Copper Canyon around 1983 and another proprietary program at the same time.

I was actually assigned to Hyper-x as a way to fail because of the extremely tight schedule and a clear reason to discharge me.

I had one hell of a team and there were only about 8-10 of us and worked long hours. We sent the finished CAD model to NASA 15 minutes before deadline.

Carl F Tarricone

Boeing Phantom Works (Retired 2009)

McDonnell Douglas Phantom Works 1983-2009)

I hope this sheds some light on this monumental vehicle in light of the current interest in Hypersonic Flight Regime.

Last edited by a moderator: