You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

General Electric/Rolls-Royce F136

- Thread starter F-14D

- Start date

Dreamfighter

'Senior Something'

- Joined

- 13 July 2008

- Messages

- 443

- Reaction score

- 522

thanks for the info

The 48 page F-35 supplement in the previous edition was very good too.

"GE and Rolls Terminate F136 and FET"

Posted by Guy Norris at 12/2/2011 10:31 AM CST

After 15 years of ups and downs, General Electric and Rolls-Royce have accepted defeat in their battle to power the F-35 Joint Strike Fighter and will today announce the end of the F136 program and the Fighter Engine Team partnership.

By deciding to discontinue self-funding the F136 alternate engine they are also parting ways at an interesting time for the propulsion world. Rolls’s recent, and unexpected, rapprochement with Pratt & Whitney over commercial engines could, for instance, signal the start of new strategic links in the military engine world now that the long-lived experiment with GE is over.

The move to kill the F136 comes after an Oct 31 meeting between GE Aviation leadership and Deputy Secretary of Defense Dr. Ashton Carter in which “it became clear that the DoD would not support the FET self-funding effort,” says GE.

Although not unexpected given the Defense Department’s termination of the F136 development effort in April this year, it ends a 15-year effort to mount a competitive challenge to Pratt & Whitney’s incumbent F135 engine for the F-35. With almost 80% of the development complete at the time of the DoD announcement, and with about $3 billion in federal funding already spent on the effort, GE and Rolls had both vowed to continue the fight by self-funding the F136 through fiscal year 2012.

However, GE says Carter’s position “made future progress on the F136 development program difficult. In addition, the status of the federal budget has created greater uncertainty for the overall JSF program.” Before the program was terminated, six F136 development engines had accumulated more than 1,200 hours of testing since early 2009. GE says that throughout its development time “the FET consistently delivered on cost and on schedule, and was rewarded with high marks by the Department of Defense in a successful joint venture between GE and Rolls-Royce.”

Source:

http://www.aviationweek.com/aw/blogs/defense/index.jsp?plckController=Blog&plckBlogPage=BlogViewPost&newspaperUserId=27ec4a53-dcc8-42d0-bd3a-01329aef79a7&plckPostId=Blog%3a27ec4a53-dcc8-42d0-bd3a-01329aef79a7Post%3a93dc8acf-d4f7-4ca0-8f3c-330bf9be12d0&plckScript=blogScript&plckElementId=blogDest

Posted by Guy Norris at 12/2/2011 10:31 AM CST

After 15 years of ups and downs, General Electric and Rolls-Royce have accepted defeat in their battle to power the F-35 Joint Strike Fighter and will today announce the end of the F136 program and the Fighter Engine Team partnership.

By deciding to discontinue self-funding the F136 alternate engine they are also parting ways at an interesting time for the propulsion world. Rolls’s recent, and unexpected, rapprochement with Pratt & Whitney over commercial engines could, for instance, signal the start of new strategic links in the military engine world now that the long-lived experiment with GE is over.

The move to kill the F136 comes after an Oct 31 meeting between GE Aviation leadership and Deputy Secretary of Defense Dr. Ashton Carter in which “it became clear that the DoD would not support the FET self-funding effort,” says GE.

Although not unexpected given the Defense Department’s termination of the F136 development effort in April this year, it ends a 15-year effort to mount a competitive challenge to Pratt & Whitney’s incumbent F135 engine for the F-35. With almost 80% of the development complete at the time of the DoD announcement, and with about $3 billion in federal funding already spent on the effort, GE and Rolls had both vowed to continue the fight by self-funding the F136 through fiscal year 2012.

However, GE says Carter’s position “made future progress on the F136 development program difficult. In addition, the status of the federal budget has created greater uncertainty for the overall JSF program.” Before the program was terminated, six F136 development engines had accumulated more than 1,200 hours of testing since early 2009. GE says that throughout its development time “the FET consistently delivered on cost and on schedule, and was rewarded with high marks by the Department of Defense in a successful joint venture between GE and Rolls-Royce.”

Source:

http://www.aviationweek.com/aw/blogs/defense/index.jsp?plckController=Blog&plckBlogPage=BlogViewPost&newspaperUserId=27ec4a53-dcc8-42d0-bd3a-01329aef79a7&plckPostId=Blog%3a27ec4a53-dcc8-42d0-bd3a-01329aef79a7Post%3a93dc8acf-d4f7-4ca0-8f3c-330bf9be12d0&plckScript=blogScript&plckElementId=blogDest

http://www.youtube.com/watch?v=DKevRqZGoMo&feature=player_embedded#!

Pity, it offered a lot. Not surprising though.

Engine Overview

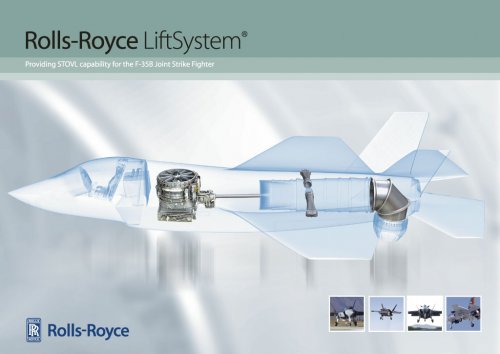

The Joint Strike Fighter (JSF) is a multi-role, single engine fighter being developed to replace a range of aircraft including the A-10, F-14, F-16, AV-8B Harrier, Sea Harrier, and F/A-18. One of the two primary propulsion systems for this aircraft is the F136.

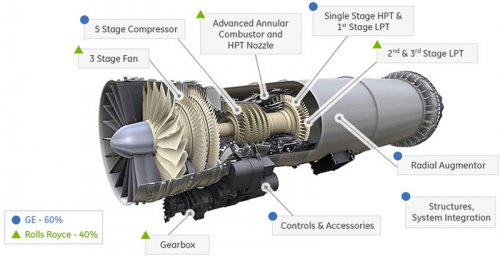

The GE Rolls-Royce Fighter Engine Team includes GE Transportation - Aircraft Engines in Cincinnati, Ohio, USA; Rolls-Royce plc in Bristol, England, and Indianapolis, Indiana, USA.

Following successful core and fan rig testing in 2000, the Fighter Engine Team ran the first full engine to test in July 2004. The first engine to test continues on schedule to deliver production F136 engines in 2011. GE, with responsibility for 60 percent of the program, is developing the compressor, coupled turbine, controls and accessories, structures and the augmentor. Rolls-Royce, with 40 percent of the program, is responsible for the fan, combustor, low-pressure turbines and gearboxes.

GE Rolls-Royce JSF F136 Program Details

PRE-SYSTEM DEVELOPMENT and DEMONSTRATION (SDD) PHASE:

PHASE I (1995-1997)

Engine definition completed

PHASE II (1997-2001)

Critical Design Review

80 hours of core testing, successful fan testing

PHASE III (2002-2005)

Detail design completed in 2002

Subsystem testing in 2002-2003

Engine systems interchangeability 2002-2003

Critical Design Review completed in 2003

First full engine to test in 2004 (same engine in endurance testing 2005)

Second full engine to run STOVL (short take-off and vertical landing) demonstration 2005

SYSTEM DEVELOPMENT and DEMONSTRATION (SDD) PHASE:

PHASE IV

Contract proposal plannning in 2004

Contract award anticipated in 2005

12,000+ testing hours

Flight test anticipated in 2009

First production engine delivery in 2011

F136 TECHNICAL CHARACTERISTICS

FRONT FAN (Rolls-Royce):

Long wide-chord, titanium, three-stage blisk

Stage one - hollow core blade; stage two & three-solid blade

Two builds tested to date, verified fan flow and efficiency

Linear friction welding for blade attachment

HIGH-PRESSURE COMPRESSOR (GE)

Five-stage, all-blisk system

Three rotors: stage one and stage two: three to five stages inertia-welded together

Forward swept airfoils, robust blade tips

Bowed/swept stators from 3-D aero codes

High-stage loading to support 40,000-pound-thrust class

COMBUSTOR (Rolls-Royce)

Single annular, simplified design

Fabricated from Lamilloy cooling material

Technology grounded in IHPTET (Integrated High Performance Turbine Engine) experience

Rig-testing ongoing

TURBINE (GE & Rolls-Royce)

Single-stage high-pressure turbine (HPT)

Three-stage low-pressure turbine (LPT)

HPT & stage 1 LPT in a coupled, vaneless counterrotating system

HP turbine blades feature single-crystal material

Successfully rig-tested

AUGMENTOR (GE)

Radial, non-stage, variable flow control

Based on GE YF120, F414-GE-100, F110-129 and F110-132 engines

Text Source:

http://www.geaviation.com/engines/military/f136/

The Joint Strike Fighter (JSF) is a multi-role, single engine fighter being developed to replace a range of aircraft including the A-10, F-14, F-16, AV-8B Harrier, Sea Harrier, and F/A-18. One of the two primary propulsion systems for this aircraft is the F136.

The GE Rolls-Royce Fighter Engine Team includes GE Transportation - Aircraft Engines in Cincinnati, Ohio, USA; Rolls-Royce plc in Bristol, England, and Indianapolis, Indiana, USA.

Following successful core and fan rig testing in 2000, the Fighter Engine Team ran the first full engine to test in July 2004. The first engine to test continues on schedule to deliver production F136 engines in 2011. GE, with responsibility for 60 percent of the program, is developing the compressor, coupled turbine, controls and accessories, structures and the augmentor. Rolls-Royce, with 40 percent of the program, is responsible for the fan, combustor, low-pressure turbines and gearboxes.

GE Rolls-Royce JSF F136 Program Details

PRE-SYSTEM DEVELOPMENT and DEMONSTRATION (SDD) PHASE:

PHASE I (1995-1997)

Engine definition completed

PHASE II (1997-2001)

Critical Design Review

80 hours of core testing, successful fan testing

PHASE III (2002-2005)

Detail design completed in 2002

Subsystem testing in 2002-2003

Engine systems interchangeability 2002-2003

Critical Design Review completed in 2003

First full engine to test in 2004 (same engine in endurance testing 2005)

Second full engine to run STOVL (short take-off and vertical landing) demonstration 2005

SYSTEM DEVELOPMENT and DEMONSTRATION (SDD) PHASE:

PHASE IV

Contract proposal plannning in 2004

Contract award anticipated in 2005

12,000+ testing hours

Flight test anticipated in 2009

First production engine delivery in 2011

F136 TECHNICAL CHARACTERISTICS

FRONT FAN (Rolls-Royce):

Long wide-chord, titanium, three-stage blisk

Stage one - hollow core blade; stage two & three-solid blade

Two builds tested to date, verified fan flow and efficiency

Linear friction welding for blade attachment

HIGH-PRESSURE COMPRESSOR (GE)

Five-stage, all-blisk system

Three rotors: stage one and stage two: three to five stages inertia-welded together

Forward swept airfoils, robust blade tips

Bowed/swept stators from 3-D aero codes

High-stage loading to support 40,000-pound-thrust class

COMBUSTOR (Rolls-Royce)

Single annular, simplified design

Fabricated from Lamilloy cooling material

Technology grounded in IHPTET (Integrated High Performance Turbine Engine) experience

Rig-testing ongoing

TURBINE (GE & Rolls-Royce)

Single-stage high-pressure turbine (HPT)

Three-stage low-pressure turbine (LPT)

HPT & stage 1 LPT in a coupled, vaneless counterrotating system

HP turbine blades feature single-crystal material

Successfully rig-tested

AUGMENTOR (GE)

Radial, non-stage, variable flow control

Based on GE YF120, F414-GE-100, F110-129 and F110-132 engines

Text Source:

http://www.geaviation.com/engines/military/f136/

Attachments

- Joined

- 9 October 2009

- Messages

- 21,131

- Reaction score

- 12,221

Regarding the P&W F135, via MilitaryPhotos.net*: http://www.star-telegram.com/news/business/article19728654.html

*One of the last, if not last, times I'll ever be saying that!

*One of the last, if not last, times I'll ever be saying that!

- Joined

- 1 April 2006

- Messages

- 11,033

- Reaction score

- 8,374

I'm looking for "Engine Design Space Exploration for a Multi-Mission Fighter Under Evolving Requirements"

by Dr. Dimitri N. Mavris, Georgia Institute of Technology

Dr. Mark Lewis, University of Maryland

http://web.archive.org/web/20110908083257/http://www.f136.com:80/jsf-engine-study

filename is GT_UMD_White_Paper_5_18.pdf

may be someoneoccasionally have it?

by Dr. Dimitri N. Mavris, Georgia Institute of Technology

Dr. Mark Lewis, University of Maryland

http://web.archive.org/web/20110908083257/http://www.f136.com:80/jsf-engine-study

filename is GT_UMD_White_Paper_5_18.pdf

may be someoneoccasionally have it?