TheKutKu

ACCESS: Secret

- Joined

- 13 February 2023

- Messages

- 411

- Reaction score

- 1,149

I stumbled upon this while reading Edward Hujsak's 1994 The Future of U.S. Rocketry. ULLV stands for "Ultra Large Launch Vehicle"

This is a concept by the "Perigee West Company of La Jolla, California", which Edward Hujsak happened to be the president of, the company got several hundred thousands usd in DoD and NASA funding in the late 80s/early 90s for several studies, I have no idea how large the company was but it at least had another employee who was another (John) Hujsak.

It follows a chapter on an hypothetical Atlas (Hujsak had worked on Atlas for decades in GD) described here https://www.secretprojects.co.uk/threads/unknown-atlas-rocket-versions.42093/#post-618804

The logic of this launcher, as described in this chapter, and a recurring theme in the work, is based on simplification of the launcher and particularly simplification of its structure. I copied the most relevant paragraphs (a lot of them aren't).

"As compared with the previous cluster concept, a SSTO will require 60 % fewer subsystems. This reduction in complexity inevitablybegs the question: Why can't the job be done with a single stage? The answer is that it can."

"If one were to take the physical size of a LOX/hydrogen rocket to extreme, surprising things happen. As the launch vehicle is made larger,< it becomes more efficient. In very large sizes, single-stage-to-orbit launch vehicle are efficient payload carriers. This is because the vehicle empty weight increases roughly as a square function, whereas its capacity for propellant increases as a cube function. The net result is a vehicle with a very high propellant mass fraction, which means it can perform well as a single-stage-to-orbit device."

So far, not different from many other proposals, what's maybe more interesting is his plan to use production lines inspired/derived from those of LNG ship tanks for manufacturing this launcher's tanks

"

Manufacturing the major components of a SSTO, which comprise thetanks and structure, involves fabrication of fairly large objects. Technology for operations of this nature has already been proven in at least one instance. During the 1970's, General Dynamics operated a production line for spherical aluminum tanks, 120 feet in diameter. The tanks were produced at a rate of one every eighteen days and shipped via barge to the shipyard where they were assembled into liquid natural gas ships."

A 1991 RAND report https://www.rand.org/pubs/notes/N3283.html also describes this "General Dynamics has produced 55 120ft-diameter aluminium alloy tanks in an LNG ship program in serial production at a cost of about $8 million each"

The book continues the description

"

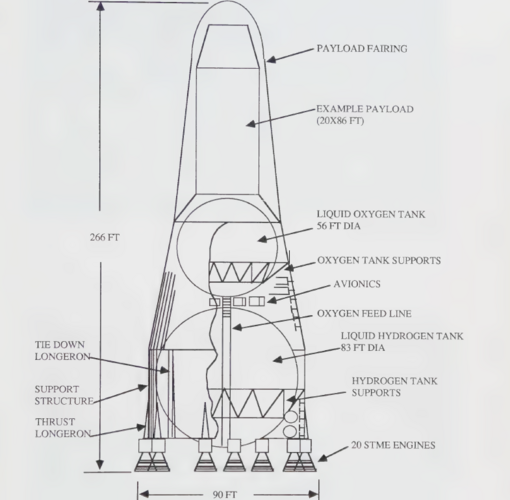

The accompanying line illustration of the " Euclid" ULLV is capable of launching 600,000 pounds into low-earth orbit. It can be used for smaller payloads by reducing the number of engines and loading the tanks to partial capacity." The tanks would apparently be made of Al-Li 2195.

"The propellant tanks are spherical and are supported by a strut system that attaches to the outer structure."

"The propellant tanks are pressurized by warm oxygen and hydrogen gas, respectively, drawn from heat exchangers on the rocket engines"

"Euclid's rocket power is provided by 20 Space Transportation Main Engines. The STME has been under development as part of the now dormant National Launch System that was recently under joint study by the DoD and NASA. The engines swivel radially on their mounts for steering. The launch vehicle lifts off at about 1.5 g and can be programmed for moderate acceleration levels by the simple process of shutting off engines at appropriate times in the launch trajectory." Curiously, Differential throttling isn't mentionned for attitude control.

"The payload fairing can protect an interior payload, or it may be part of a payload, for example a shielded spacecraft or a propellant carrier."

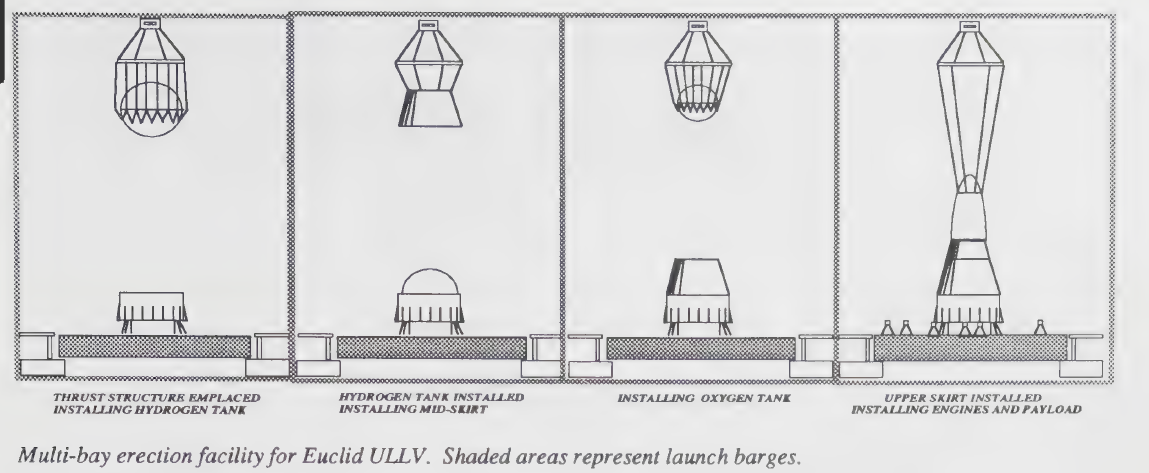

"Assembly of the Euclid ULLV is planned to take place on launch barges, which would be dry-docked inside large buildings during theassembly process. The major vehicle elements would be hoisted into place and fastened together. The ULLV is secured to launch pedestals and stands over an opening in the barge through which engine exhaust is ported at liftoff."

"

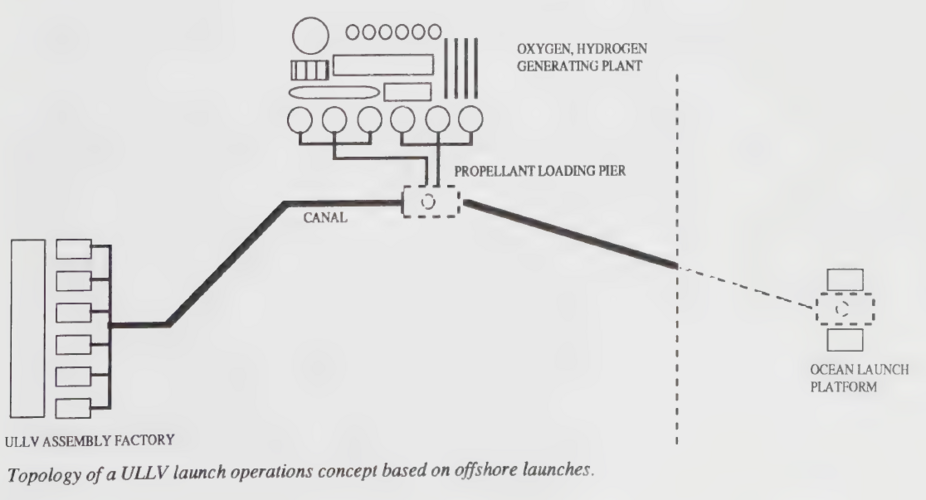

The launch barges are fitted internally with propellant loading equipment which can be remotely operated. One operations plan is to launch the ULLV on a sea platform. In this case the barge would dock at a loading station to take on propellants before being towed to the launch station.

Hydrogen and oxygen could be generated locally, or they could be transported to local storage tanks from a distant production facility."

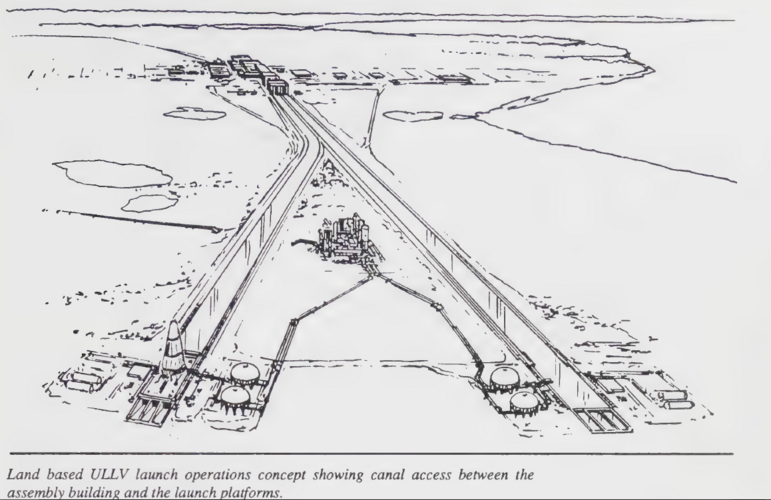

"A second plan centers on land-based launch operations. In this arrangement the barges do not carry propellants. The vehicle is instead loaded from large storage tanks adjacent to the launch station. As in the case above, the propellants can be either manufactured locally or trucked in.

Probably the major issues to be resolved in installations of this type are local environmental impacts. In a high launch rate situation, acoustic loads alone could be the driver for offshore operations."

"

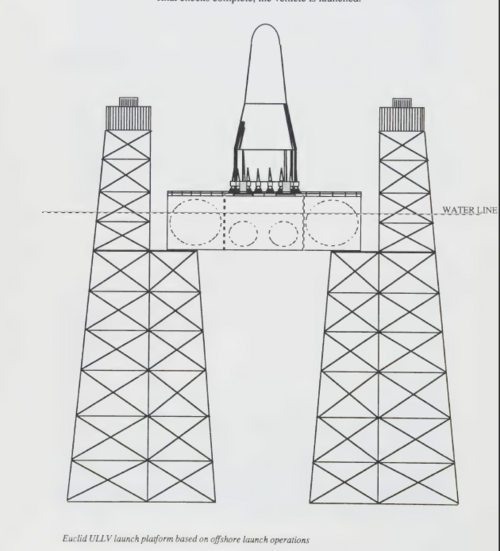

In the ocean launch operations scheme, the launch barge with the empty ULLV, secured to its launch pedestals, is towed to a location between twin ocean platforms. It is then ballasted to rest on a submerged section of the platform where it is secured in place. The launch vehicle is loaded by remote control from the propellant tanks inside the launch barge. With

final checks complete, the vehicle is launched.

Hujsak then puts it bluntly: "No missions, or even requirements currently exist for a ULLV", which is why he suggests a Mars mission (and namedrops Space-based solar power, without developing it further)

"A necessary feature of the expedition equipment will be gravity spacecraft. It makes no sense to risk landing weakened or crippled astronauts on the surface of Mars, a condition that can result from many months in zero gravity. A second required feature will be safety. The spacecraft will have to contain sufficient redundancy, power and shielding to assure ability to get out of trouble, should problems occur during he mission. The third feature should be provisions for creature comfort. The Mars trip will be by far the most difficult manned mission yet tried.

But the greater part of the mission will be time spent in transit.

Most spacecraft functions will be automated to reduce possibilities of human error. ULLV's will make it possible to achieve the above capability. The luxury of very large lift capability provides designers with the margins needed for a truly robust system."

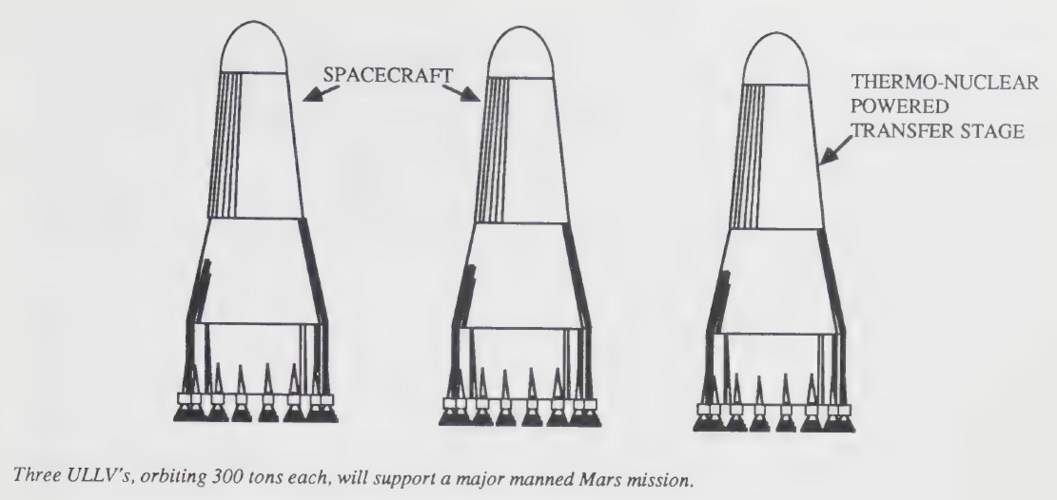

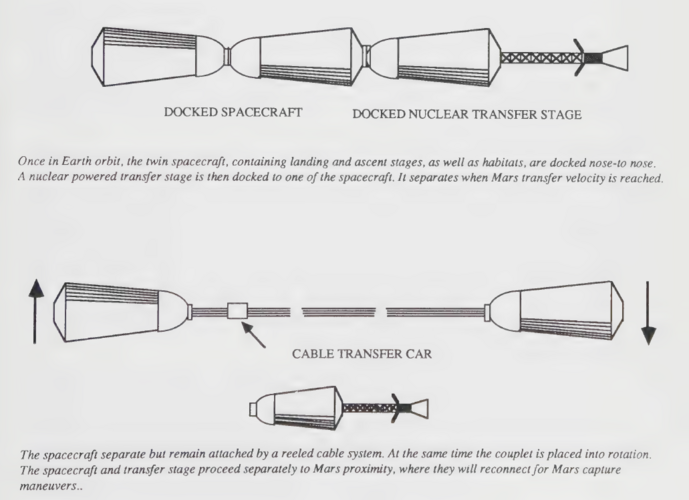

"One plan for providing in-transit artificial gravity as well as safety and comfort assumes a mission that is performed with two large redundant spacecraft, coupled and rotated in a manner to produce artificial gravity. A meaningful manned Mars mission with these features could be accomplished with three ULLV flights. Two flights would be dedicated to launching the two spacecraft into low-earth orbit, where they would be coupled together. A third flight would launch a nuclear powered transfer stage. This stage would have sufficient capacity to accelerate the spacecraft pair toward Mars, as well as power the much lighter pair on the earth return trajectory at the conclusion of the mission.

"The gravity spacecraft will be made possible by development of very high tensile material for cable construction. Commercial carbon fibers are already available with tensile strengths exceeding one million pounds per square inch. Materials of much higher strength are under development in several laboratories. A leading candidate may be derived from complex carbon molecules, recently discovered, termed "fullerenes." The name honors Buckminister Fuller, as the molecules exhibit an architecturesimilar to Fuller's geodesic domes. The carbon clusters are also known as "buckyballs." A new carbon fiber material designated "buckytubes," has followed the discovery of buckyballs."

"When the two spacecraft are mechanically docked, dual cable-and-reel subsystems in the nose sections are interlocked. An integral part of thesubsystem is a transfer car, operating along the cables, that enables crew passage between the spacecraft."

"The propulsion unit has three major components, a hydrogen tank , a control avionics, and a thruster. It provides propulsion for the entire mission. The hydrogen tank is fitted with propellant recovery equipment to prevent loss of hydrogen during the years-long mission. Development of a high temperature reactor will simplify the system, allowing use of ordinary water as the propulsion medium. The rocket engine, with its associated pumping and control equipment, will consist of one or more thermonuclear reactors. Multiple reactors will be required in the event that an "engine out" capability is deemed necessary."

The RAND report describes an even larger launcher:

"Principal elements of the total system are the launch vehicle (LV), a multibay LV erection facility where vehicles are assembled on launch barges in dry dock, a metals fabrication factory to support the erection facility, launch barges equipped with propellant loading facilities below deck, canal access to the ocean, a way-station where LOX and LH2 are generated for loading into the barge propellant tanks, and an oil platform structure at sea constructed so that the barge (from which the vehicle is launched) can be floated over pedestals and secured by ballasting."

"The LV is a smooth, conical, single-stage design, 300 ft tall with a 138-ft maximum diameter. Hydrogen is contained in a 120-ft-diameter sphere mounted atop a toroidal LOX tank. General Dynamics has produced 55 120-ft-diameter aluminum alloy tanks in an LNG ship program in serial production at a cost of about $8 million each. The vehicle gross liftoff weight is 28.4 million pounds, providing 1.5 million pounds of payload to LEO for a payload-to-gross-weight ratio of 0.053. Liftoff thrust is 36 million pounds, using 18 2-million-pound thrust engines based on M-1 engine technology (see Sec. II). A single-stage propellant mass fraction of about 0.94 is required and believed achievable. The author estimates that the LVs could be produced for $150 million each, the total system for under $10 billion in less than ten years, and that payload could be delivered to LEO for about $100/lb. The concept stresses simple design using ALS-type cost-reduction principles in conjunction with the demonstrated H2 tank fabrication techniques."

Definitely optimistic

There aren't many references to this launcher online, in 2016, before Hujsak's passing, he briefly commented on his blog about some of the similarities between Musk's 2016 ITS presentation and his ULLV concept. From that blog, he definitely believed in Martian colonisation for the preservation of mankind. It's sad that he never got to see Starship fly.

This is a concept by the "Perigee West Company of La Jolla, California", which Edward Hujsak happened to be the president of, the company got several hundred thousands usd in DoD and NASA funding in the late 80s/early 90s for several studies, I have no idea how large the company was but it at least had another employee who was another (John) Hujsak.

It follows a chapter on an hypothetical Atlas (Hujsak had worked on Atlas for decades in GD) described here https://www.secretprojects.co.uk/threads/unknown-atlas-rocket-versions.42093/#post-618804

The logic of this launcher, as described in this chapter, and a recurring theme in the work, is based on simplification of the launcher and particularly simplification of its structure. I copied the most relevant paragraphs (a lot of them aren't).

"As compared with the previous cluster concept, a SSTO will require 60 % fewer subsystems. This reduction in complexity inevitablybegs the question: Why can't the job be done with a single stage? The answer is that it can."

"If one were to take the physical size of a LOX/hydrogen rocket to extreme, surprising things happen. As the launch vehicle is made larger,< it becomes more efficient. In very large sizes, single-stage-to-orbit launch vehicle are efficient payload carriers. This is because the vehicle empty weight increases roughly as a square function, whereas its capacity for propellant increases as a cube function. The net result is a vehicle with a very high propellant mass fraction, which means it can perform well as a single-stage-to-orbit device."

So far, not different from many other proposals, what's maybe more interesting is his plan to use production lines inspired/derived from those of LNG ship tanks for manufacturing this launcher's tanks

"

Manufacturing the major components of a SSTO, which comprise thetanks and structure, involves fabrication of fairly large objects. Technology for operations of this nature has already been proven in at least one instance. During the 1970's, General Dynamics operated a production line for spherical aluminum tanks, 120 feet in diameter. The tanks were produced at a rate of one every eighteen days and shipped via barge to the shipyard where they were assembled into liquid natural gas ships."

A 1991 RAND report https://www.rand.org/pubs/notes/N3283.html also describes this "General Dynamics has produced 55 120ft-diameter aluminium alloy tanks in an LNG ship program in serial production at a cost of about $8 million each"

The book continues the description

"

The accompanying line illustration of the " Euclid" ULLV is capable of launching 600,000 pounds into low-earth orbit. It can be used for smaller payloads by reducing the number of engines and loading the tanks to partial capacity." The tanks would apparently be made of Al-Li 2195.

"The propellant tanks are spherical and are supported by a strut system that attaches to the outer structure."

"The propellant tanks are pressurized by warm oxygen and hydrogen gas, respectively, drawn from heat exchangers on the rocket engines"

"Euclid's rocket power is provided by 20 Space Transportation Main Engines. The STME has been under development as part of the now dormant National Launch System that was recently under joint study by the DoD and NASA. The engines swivel radially on their mounts for steering. The launch vehicle lifts off at about 1.5 g and can be programmed for moderate acceleration levels by the simple process of shutting off engines at appropriate times in the launch trajectory." Curiously, Differential throttling isn't mentionned for attitude control.

"The payload fairing can protect an interior payload, or it may be part of a payload, for example a shielded spacecraft or a propellant carrier."

"Assembly of the Euclid ULLV is planned to take place on launch barges, which would be dry-docked inside large buildings during theassembly process. The major vehicle elements would be hoisted into place and fastened together. The ULLV is secured to launch pedestals and stands over an opening in the barge through which engine exhaust is ported at liftoff."

"

The launch barges are fitted internally with propellant loading equipment which can be remotely operated. One operations plan is to launch the ULLV on a sea platform. In this case the barge would dock at a loading station to take on propellants before being towed to the launch station.

Hydrogen and oxygen could be generated locally, or they could be transported to local storage tanks from a distant production facility."

"A second plan centers on land-based launch operations. In this arrangement the barges do not carry propellants. The vehicle is instead loaded from large storage tanks adjacent to the launch station. As in the case above, the propellants can be either manufactured locally or trucked in.

Probably the major issues to be resolved in installations of this type are local environmental impacts. In a high launch rate situation, acoustic loads alone could be the driver for offshore operations."

"

In the ocean launch operations scheme, the launch barge with the empty ULLV, secured to its launch pedestals, is towed to a location between twin ocean platforms. It is then ballasted to rest on a submerged section of the platform where it is secured in place. The launch vehicle is loaded by remote control from the propellant tanks inside the launch barge. With

final checks complete, the vehicle is launched.

Hujsak then puts it bluntly: "No missions, or even requirements currently exist for a ULLV", which is why he suggests a Mars mission (and namedrops Space-based solar power, without developing it further)

"A necessary feature of the expedition equipment will be gravity spacecraft. It makes no sense to risk landing weakened or crippled astronauts on the surface of Mars, a condition that can result from many months in zero gravity. A second required feature will be safety. The spacecraft will have to contain sufficient redundancy, power and shielding to assure ability to get out of trouble, should problems occur during he mission. The third feature should be provisions for creature comfort. The Mars trip will be by far the most difficult manned mission yet tried.

But the greater part of the mission will be time spent in transit.

Most spacecraft functions will be automated to reduce possibilities of human error. ULLV's will make it possible to achieve the above capability. The luxury of very large lift capability provides designers with the margins needed for a truly robust system."

"One plan for providing in-transit artificial gravity as well as safety and comfort assumes a mission that is performed with two large redundant spacecraft, coupled and rotated in a manner to produce artificial gravity. A meaningful manned Mars mission with these features could be accomplished with three ULLV flights. Two flights would be dedicated to launching the two spacecraft into low-earth orbit, where they would be coupled together. A third flight would launch a nuclear powered transfer stage. This stage would have sufficient capacity to accelerate the spacecraft pair toward Mars, as well as power the much lighter pair on the earth return trajectory at the conclusion of the mission.

"The gravity spacecraft will be made possible by development of very high tensile material for cable construction. Commercial carbon fibers are already available with tensile strengths exceeding one million pounds per square inch. Materials of much higher strength are under development in several laboratories. A leading candidate may be derived from complex carbon molecules, recently discovered, termed "fullerenes." The name honors Buckminister Fuller, as the molecules exhibit an architecturesimilar to Fuller's geodesic domes. The carbon clusters are also known as "buckyballs." A new carbon fiber material designated "buckytubes," has followed the discovery of buckyballs."

"When the two spacecraft are mechanically docked, dual cable-and-reel subsystems in the nose sections are interlocked. An integral part of thesubsystem is a transfer car, operating along the cables, that enables crew passage between the spacecraft."

"The propulsion unit has three major components, a hydrogen tank , a control avionics, and a thruster. It provides propulsion for the entire mission. The hydrogen tank is fitted with propellant recovery equipment to prevent loss of hydrogen during the years-long mission. Development of a high temperature reactor will simplify the system, allowing use of ordinary water as the propulsion medium. The rocket engine, with its associated pumping and control equipment, will consist of one or more thermonuclear reactors. Multiple reactors will be required in the event that an "engine out" capability is deemed necessary."

The RAND report describes an even larger launcher:

"Principal elements of the total system are the launch vehicle (LV), a multibay LV erection facility where vehicles are assembled on launch barges in dry dock, a metals fabrication factory to support the erection facility, launch barges equipped with propellant loading facilities below deck, canal access to the ocean, a way-station where LOX and LH2 are generated for loading into the barge propellant tanks, and an oil platform structure at sea constructed so that the barge (from which the vehicle is launched) can be floated over pedestals and secured by ballasting."

"The LV is a smooth, conical, single-stage design, 300 ft tall with a 138-ft maximum diameter. Hydrogen is contained in a 120-ft-diameter sphere mounted atop a toroidal LOX tank. General Dynamics has produced 55 120-ft-diameter aluminum alloy tanks in an LNG ship program in serial production at a cost of about $8 million each. The vehicle gross liftoff weight is 28.4 million pounds, providing 1.5 million pounds of payload to LEO for a payload-to-gross-weight ratio of 0.053. Liftoff thrust is 36 million pounds, using 18 2-million-pound thrust engines based on M-1 engine technology (see Sec. II). A single-stage propellant mass fraction of about 0.94 is required and believed achievable. The author estimates that the LVs could be produced for $150 million each, the total system for under $10 billion in less than ten years, and that payload could be delivered to LEO for about $100/lb. The concept stresses simple design using ALS-type cost-reduction principles in conjunction with the demonstrated H2 tank fabrication techniques."

Definitely optimistic

There aren't many references to this launcher online, in 2016, before Hujsak's passing, he briefly commented on his blog about some of the similarities between Musk's 2016 ITS presentation and his ULLV concept. From that blog, he definitely believed in Martian colonisation for the preservation of mankind. It's sad that he never got to see Starship fly.

Last edited: