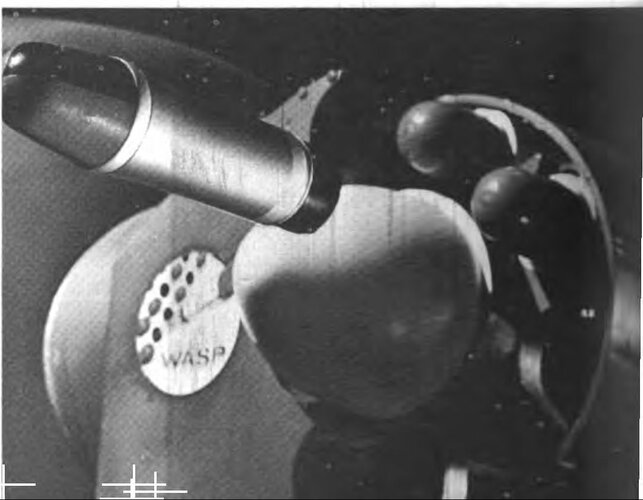

WASP

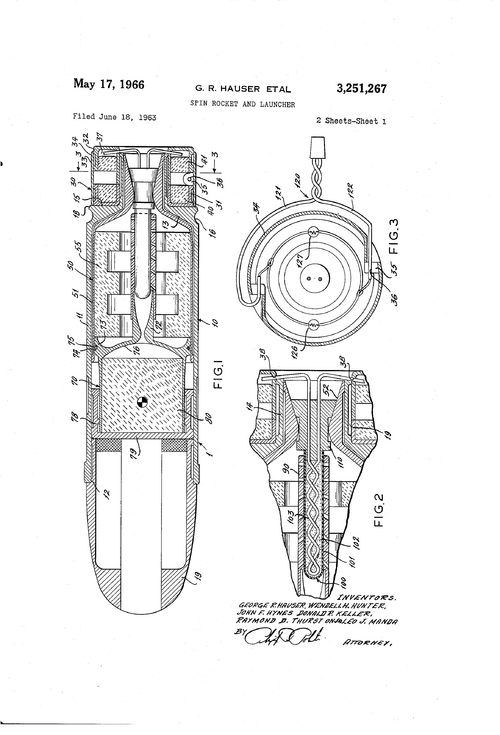

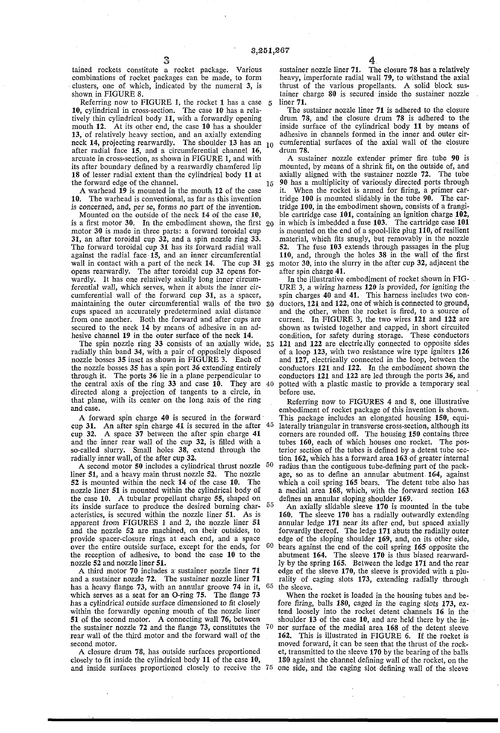

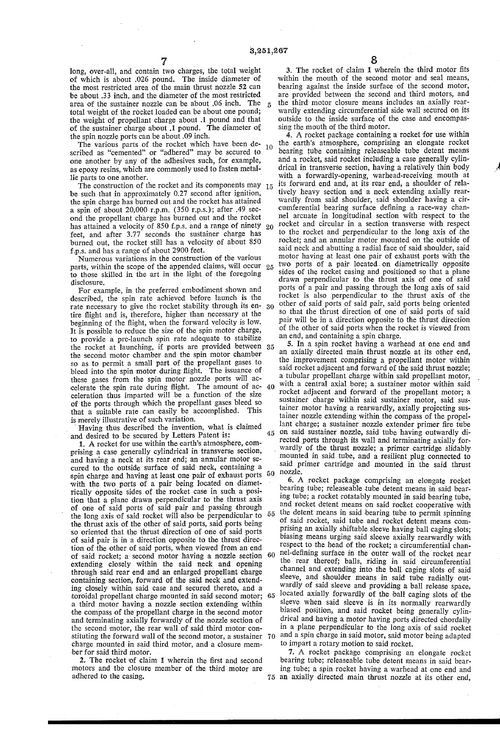

As developed by Emerson Electric for the U. S. Army Missile Command, the spin-stabilized WASP rocket motor incorporated separate spin, boost , and sustain propulsion systems. The initial motor design used two end-burning grains of a non-aluminized polysulfide propellant for the spin motor, a five-point "star" configuration of the same propellant for the boost motor, and an end-burning alkyd-resin styrene composite for the sustain motor. Company. All propellants were supplied by Bermite Powder As zeported in (l), boost thrust measurements obtained at radial acceleration levels decaying from about 7000 G's to zero at burnout gave no positive indications of any significant effect of the spin environment on motor performance. The revised WASP motor design incorporated a cylindrically perforated grain of 1% aluminized polyvinyl chloride propellant (Arcite 386M) for the spin motor, a 6-point "star" configuration of the same propellant for the boost motor, and an end-burning non-aluninized polyvinyl chloride composite (Arcite 377A) for the sustain motor. section, patterned after those developed at the Naval Weapons Center (NOTs). propellan3s were supplied by Atlantic Research Corporation. The sustain motor also incorporated a vortex spoiler in the nozzle entrance All As reported in (2), the effects of radial accelerations increasing from 0 to approximately 16,000 G's on spin motor performance were found to be primarily a result of propellant/case structural interactions, with some burn rate amplification due to combustion effects also likely, but undefined (4). In order to achieve simultaneous burnout of both the struts and periphery of the boost grain at 16,000 GIs, the peripheral web thickness was increased about 30% during this development program. under spin was primarily due to alumina centrifugation (4) or preferential peripheral ignition of the grain under spin (2) was not resolved. Whether the apparent 30% increase in burn rate With the vortex spoiler incorporated in the sustainer nozzle, the end-burning sustain motor was essentially neutral burning (2), (4). However, a concurrent test program conducted at Redstone Arsenal (3) with the same non-aluminized propellant indicated severe centerline coning of the grain at radial accelerations of only 3500 G's when the vortex spoiler wa$ not incorporated in the nozzle. -1 I a, 1 1% "e/ I

References

(1) T. F. HOEKEL and L. J. MANDA: "The Influence of the Spin Environment on the WASP Booster Performance?'; Symposium on the Behavior of,Propellants Under Acceleration Fields; Naval Ordance Test Station; NOTs TP377Q; June 1965; AD-363903; (C).

(2) "Final Report - WASP Advanced Development Program"; Volume I; Eherson Electric Report No. 2030; February 1966; AD-373484; (C).

(3) D. R. ULLOTH and W. D. GUTHRIE: "A Study of Vortex Effects in Spinning Rocket Motors"; Report RK-TR-66-8; April 1966; AD-374624; (C).

(4) P. W. SERBU; ET AL: "WASP Motor Development Program"; presented at ICRPGIAIAA Solid Propulsion Meeting , Washington, D. C ; 19-21 July 1966 ; - CPIA Publication No. 111; Volume 11; pp. 485-507; AD-373908; (C)