- Joined

- 27 December 2005

- Messages

- 16,924

- Reaction score

- 21,798

Archived fromProject 'Blue Sky' (Fireflash) and Ekco

Blue Sky (Fireflash) memories by Ken Sims

Blue Sky Anti Aircraft Missile

Photograph courtesy of

The RAF Museum

Blue Sky Anti Aircraft Missile

Photograph courtesy of The RAF Museum

Background

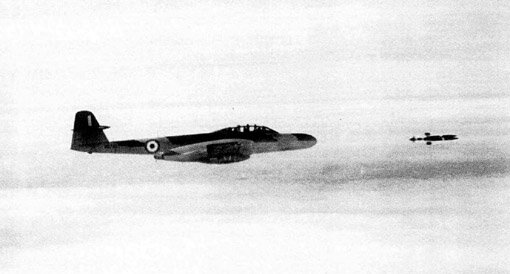

In 1947, Fairey Aviation started development of what was to become Britain's first 'Air to Air' guided missile. This missile was primarily designed to counter the threat posed by enemy bomber aircraft although it was also hoped that it could be used against enemy fighter aircraft.

This missile program, which was 'top secret' (for obvious reasons) was given the code name 'Blue Sky' so as to not give any indication of the purpose of the project. Only later when the project moved to the trials squadron stage was the missile called 'Fireflash'

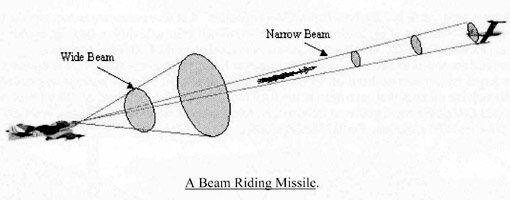

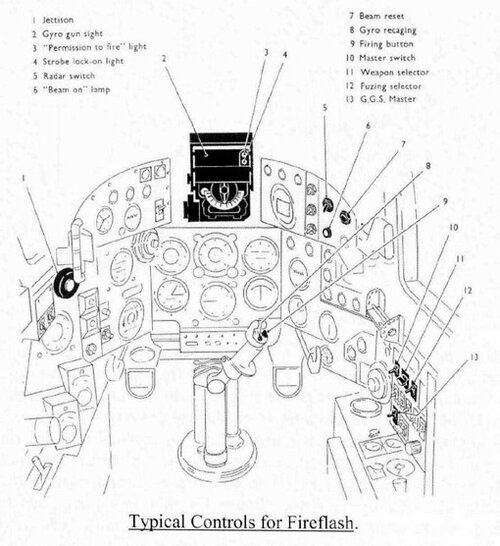

At the time of development, Air-launched Anti Aircraft Missile technology was in its infancy and none of the 'homing' mechanisms used on modern missile systems had been designed, so, using radar 'lock-on' technology developed during the war, the missile was designed to be a 'beam riding' missile, whereby the host fighter would lock a very narrow radar beam onto the aircraft to be attacked and after launch, the missile would centre itself onto the beam and fly along the beam until it reached the target.

By 1952, the project had developed to the stage that all the design of missile was mostly done and the missile was first flown from a test platform at the Larkhill test area on Salisbury plain.

EKCO's role in the project was to design and develop the radar suite in the host aircraft and the radar developed was an X band system using a helical Scan dish, which had a small amount of 'nod'.

Fairey Aviation described the system as 'Radar Ranging Mark 2' but this description was not accepted by EKCO who did not consider this an accurate name.

The radar had a capability of up to 10 miles in range but was only intended for use at approximately 5 miles although would be fired at about 2 miles during tests but a bit further (or shorter) in anger as the pilot chose.

The following pages are the first hand account of Ken Sims who was closely involved with the project.

My first connection with Blue Sky was when I got a job at EKCO Malmesbury as Laboratory Assistant. It was 1953 and I had just left the Navy with no qualifications and little else to recommend me, as I was basically Aircrew. But I was familiar with the early radar and a colleague at Lee-on-Solent who had been to Malmesbury as a Chief Radio Mechanic told me to write to Mr.PL Stride.

My interview with Mr. Stride lasted some hours and though he soon found out what I didn't know and I felt I had failed miserably, he must have seen some promise as to my amazement he offered me a job although it was a big comedown from the money I got as a Chief Petty Officer but at the time I was grateful for any kind of job.

I was attached to Mr. David Evans who himself had been commissioned as an RNVR officer in the Radio/Electrical sphere. I discovered that we were responsible for the TR Unit for this new project. Also in our Lab. but independent to us, were Mr. Cyril Drew assisted by Bill Graville who was designing the Drive Modulator Unit, which would feed into the TR to drive the Magnetron.

It was ages before I began to understand what the project was all about, not only was there an air of secrecy but even when they began to tell me this and that I still didn't really understand. I was the proverbial dim beginner.

Our first step was design of transformers to power the unit. Two years later I might have been able to do it on my own but initially David did the design and I was set the task of wiring up and testing. We used oil-filled transformers to dissipate the heat. I further learnt that the TR would be in a sealed box with a heat exchanger on the front to dissipate the heat generated.

The exchanger was like a car radiator with air pumped through to keep it cool. We had been expecting to put in some chokes in the power supply system that would act as swinging chokes, but in all my testing and measurements at various loads I saw no sign that they were acting this way.

Note: Some two years after we did the design, someone had a thought about oil-filled transformers. 'What if the oil leaked and happened to spray on a hot wire-wound resistor'? They tried this out and the box exploded!! By then we were committed and just went on hoping that our transformers were not overstretched and that few wire wound resistors were anywhere nearby!

By now I was beginning to learn what else was going to go in our box. We would have the Magnetron and a Pulse Transformer. Also various bits of wave-guide known as a rat race which with spark-gaps would determine whether in transmission mode or receiving. There would also be an IF strip as initial amplification when receiving and an AFC strip to match the receiver to the magnetron frequency.

As I barely understood any of this I was directed towards reading and learning the M.I.T. Manuals. (Massachusetts Institute of Technology) who had done much of the experimental work during the war once they had been directed towards the original British ideas? This was hard going, as you may well guess.

I was also advised to take on a Course at Chippenham Technical College, where the course contents were influenced by the proximity of Westinghouse, who provided most of the scholars.

Thus it was all electrical motors and generators plus the catenaries of sagging power lines between pylons. They let me start on the third year because I already had S1 and S2 from my pre-war studies in the field of architecture. So now I was swotting-up in two different fields though loosely connected.

How could I fit all this in together with my love for a few pints in the evening? I sure burnt the midnight oil, I can tell you.

I did start to earn my keep when it came to directing the efforts of the Development Assembly Department. These chaps put together the early models after the labs had had their first go with lab built layouts and croc clips dangling all over the place. They brought in the professional touch of proper soldering without dry joints.

However, they had a typical contempt for the engineers, who may have understood the theory but were not exactly practical. Johnnie Rocket, for example was renowned for encircling himself with croc clip wires and then trying to walk away to answer the phone.

So these Assemblers tried me out with the usual deliberate mistakes to catch out an engineer. It didn't work and I came down on them like a ton of bricks. After that we got along fine, though I do recall that when I first assembled the duplicate rat races I found it necessary to put in two screws before linking them together. I wrote this out and stressed the point. Yet, clever blighters that they were, they ignored my advice. So they finished up with an assembly, which was minus two screws inside. And they had done it with 5 assemblies!!

After this my status went up considerably and there was no more argument, as they had to dismantle and reassemble all 5 of them.

I started to pull my weight when it came to the layout inside the box. For this I had to co-operate with the draughtsman who would draw it up. We had just about met the needs, including all the limitations imposed by the Ministry to meet maximum dimensions of possible replacements from different sources when they dropped a bombshell on us and required the TR Unit to be made two inches shorter.

While it doesn't sound much, it made life very difficult. We eventually succeeded in cutting it down but we had to utilise every bit of space, not helped by the fact that some of the bits like the IF strip and the AFC were designed outside of our lab, we just put them in the box.

I think it was the second Christmas I was there when I was tasked to wire up and assemble the first full unit. By now it was agreed that my standard of soldering was acceptable to pass the most stringent inspectors and I was cleared for overtime over the Christmas period to bring the first box up to operating standard.

But first the lab (and everyone else) adjourned for a pre-Christmas drink. Knowing that I was likely to return that evening they hid the box away from me to prevent any disaster. I came back but couldn't find it!! Next morning, more sober, I found where they had hidden it, up in the loft of this old house, which was full of odd corners.

We finally got the box to start operating and our power supplies drove all the other added units. I should perhaps digress a bit here and say that I had been active in testing out the running of our Magnetron Units, which were quite high power. I spent many hours setting up the drive to run them inside a vacuum tank.

I have to laugh these days when I read of people getting all hot-under-the-collar about mobile masts. By now I should be cooked to a frazzle and presumably unable to father even an alien!! I did make sure it wasn't pointed at me but there was a load on the Magnetron output.

One major disaster we had was the fact that the AFC was simply not working correctly; the frequency was flopping about all over the place. It would lock-on, fall off and lock on everywhere. To sort out the problem, we had to call in the wave-guide experts who decreed that the Magnetron was not just pushing the power out into the wave-guide it was also squirting it out of its cathode stem.

This was the place where we first had to cook it up with a warming current until it was ready to oscillate whence the warm up would be switched off. All this was in a screening box but the stuff was still getting out. So we had to fit a frequency designed collar round the cathode, which finally worked after various design attempts.

Meanwhile of course we were all getting a nice dose of microwave energy, even so we succeeded in producing maybe six development models all of which had to be tested in the labs.

It was about this time that I was sent up to (RAF) Valley to relieve Tony Marzetti for a couple of weeks. We didn't really do anything except help train the RAF ground crews to check out the boxes. We were only there as consultants.

Perhaps I should digress for a moment to describe my progress at the Tech. College. I had done well in the first year, which was the third towards an Ordinary Certificate and I got 98% in Mathematics, which was duly flashed around the Works and gave me a little bit of status though I was still very ignorant about circuitry. We were still using hot-filament valves.

Next I embarked on a further two years to obtain an H.N.C. Still all in the field of electrics, I completed my exams in the fifth year for the H.N.C but the results came through later (when I was in Woomera), which confirmed I had passed with Honours in Mechanics

In respect of Woomera, a further series of Fireflash trials were arranged there because of the weather and size of the range, and EKCO people had to go to act as consultants.

We were each to go for three months. Brian Wells first, then me, and I can't remember who was to follow me. Except that after I got out there, via a Transport Command Hastings, which took a week, the Suez Canal crisis blew up.

This meant that not only were the Hastings otherwise employed but they couldn't fly across Egypt. So I was trapped. Some senior people could be shifted in and out by a different route and in commercial airlines but that didn't apply to me.

At Woomera itself I had to use the Senior Mess and although a civilian I was ranked at the level of Squadron Leader. As an ex-serviceman this was very much my sphere and the RAF are not so particular as the Royal Navy. I was very soon accepted into the circle of the Mess activities.

As soon as they learnt about my past history as an aviator I was invited to occupy the back seat in a Meteor IV. This wasn't what I was there for but they welcomed another Observer who would not be sick in the back and knew where they were. This continued throughout my stay

Before I went, I was given crash courses in the other parts of the system about which I knew little or nothing though I was aware that other labs were involved. So now I had to swot up on the circuitry, which was the sphere of all the other clever blighters who talked in obscure phrases, which went over my head. I learnt that our box (not mine theirs - I forget what it was called) had memory!! If there was a target it would clock up as a charge on a capacitor - I could understand this bit. Then on the next sweep of the scanner it would check to see if the same target was there. If not it was wiped clean. If still there it would enhance the signal.

I began to understand this. But the signal might just be background noise, which was intermittent. So the result was that the unit was able to isolate and lock onto signals, which were below noise levels. I think I understood this. But it was very different when faced with an array of valves whose grids and anodes went up and down to a point where one wasn't sure where they should be. So I nodded intelligently and moved on to the key part of the instruction, which concerned the aerial.

I was aware that this dish didn't go from side to side like the usual scanner but rotated (Helical Scan) with a small amount of nod. This, it was fairly evident produced a transmit pattern which had a centre-line or beam and a circulatory pattern outside of the main beam.

The centre of the transmission was strong enough to be considered a beam.

It wasn't difficult to understand that the receiver (which was fitted at the back of the missile - made by Fairey Aviation) would see this beam and could arrange to get itself in the centre of the beam. If the signal was weak it would aim to move into the middle - but which way? I will come to this later.

But first of all had we had to check that we had got the scanner pointing down the centre line of the aircraft? The set-up to check this out consisted of a pole up which there was a small horn aerial connected to a low power transmitter - a klystron. The scanner was arranged to look at this transmitter and careful adjustments made to get this fully centred in the beam. Such adjustments consisted of adding or removing washers at the prime fixings.

The joke was guessing which way to move it. The experts described imagining you were standing on your head in order to work out which way was which. I had watched some of the men from the Ministry having this described to them and been amused at their antics in getting the idea.

They had also been introduced to our box, which produced targets to lock onto. It was suitably fronted with switches marked up/down left/right. There was a button marked 'fly'. Inevitably one of them asked what it did. Had they not heard of a 'fly-button'?

I soon found out how to set the scanner for the centre line of beam, but it was clear that there were so many different electrical connections in the system that it was evident that it was easily possible to get the wrong set of signals controlling the outer sweeps of the scan. In such circumstances the missile would get the wrong indications and be thrown off the beam instead of moving into the centre.

During our set-ups we could ensure that this was correctly aligned to draw in rather than throw out and so lining up the scanner became a prime part of our duty and presence at the test site.

I really only had to keep the various Scanners lined up and spent some time repairing another test-box that we had developed. I joined in as a soccer player during their winter and as a cricket player in their summer.

Due to these social activities, it was hardly surprising then that when I couldn't return I said not to worry I'd stay there for the rest of the trials. But they had recruited this other chap specifically so he was sent anyway.

http://www.ekco-radar.co.uk