Actually, in most ways, American quality exceeded what the Germans were producing. For example, the US magnafluxed every round of antitank ammunition they produced. US tank transmissions used double helix gear drives that were stronger and more reliable than the single cut gears the Germans were using.

In part, it is because Germany didn't have the tooling to do otherwise, and in part because of the drastic state of industry in Germany as the war progressed, such as the increasing use of foreign and slave labor.

And meanwhile, what were the Germans doing?

They had their own problems, of supply, caused by the naval blockade.

German industry was not able to produce the specially heat and stress-resistant

metallic alloys that were required. They lacked metals like the chromium and

molybdenum that were essential to harden the steel. Germany had exhausted their

stocks and could not import them during the war, as also happened with rubber

and oil.

The chemists produced silicones to replace the rubber and made synthetic oil of low

quality from coal, but the ceramic materials for the compressor blades of the turbojets

would not be ready on time and everyone knew it.

The lack of oil suffered by Germany during the last year of the war induced scientists

and engineers to experiment with alternative fuels.

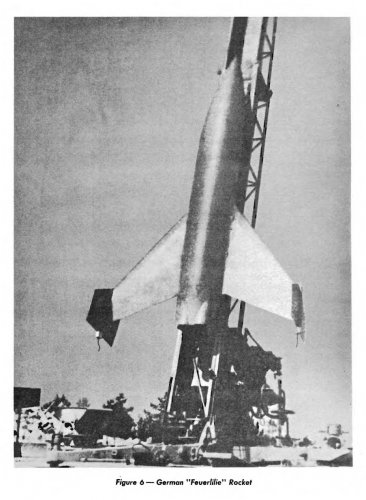

The most refined gasoline was used for conventional piston engines. The BMW 003

turbojets worked with B.4 (87 octane petrol). The J2 and K1 burnt by the Jumo 004 and

Heinkel HeS 011 turbojets were heavy kerosenes. The Argus pulsejet of the V-1 worked

with crude oil. The Peenemünde engineers designed a V-2 that worked with diesel

oil and S-Stoff. Dr Pabst, from the Gas Dynamics section of the Focke Wulf company,

suggested that the ramjets of the future Triebflügel fighter burn even less volatile fuels,

such as pitch oil or lignite tar. To that end, they had to design a compact evaporating

plant that could be installed onboard.

This situation particularly affected the conventional piston engines. The poor

ratings of the 87 octane B4 fuel and the poor quality of Schmiertoff lubricant, which

obliged engines to be run at high revolutions to deliver the required horsepower, were

the cause of numerous problems, while deficient Kühlsotff (50 per cent glycol, 50 per

cent water) cooling, vibration fractures and disintegration of bearings, due to shortage

of tin during its manufacturing, caused corrosion and piston seizure.

To avoid these deficiencies, some engines were redesigned with bigger cylinders and

twin (three-speed) superchargers, due to the poor performance (just thirty minutes)

of the one-stage superchargers of first generation.

Attempts were also made to improve performance using two new power boost

injection systems, the GM-1 (liquid nitrous oxide) for altitudes over 10,000 metres and

the MW-50 (50 per cent methanol, 49.5 per cent water and 0.5 per cent Schutzöl 39

anticorrosion fluid) for emergency power boost at medium altitude.

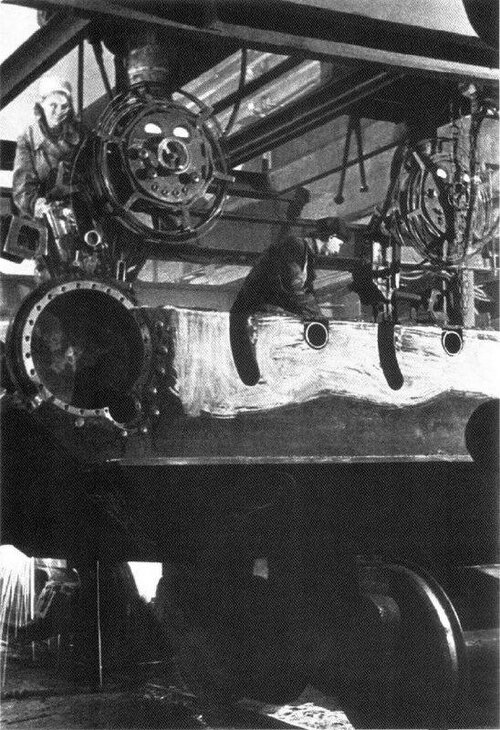

In spite of all these issues, the reliability of the new BMW 003 and Jumo 004

turbojets, and the HWK 109 rocket engine was so low that the Oberkommando

der Luftwaffe allowed the development of some piston engines to continue until

February 1945.

As NASA did in the 1960s, the German aeronautical industry was forced to compen-

sate the lack of power of their engines with high technology solutions – in the 1960s it

was microelectronics to save weight, in the 1940s, it was aerodynamics.