- Joined

- 24 November 2008

- Messages

- 1,401

- Reaction score

- 1,949

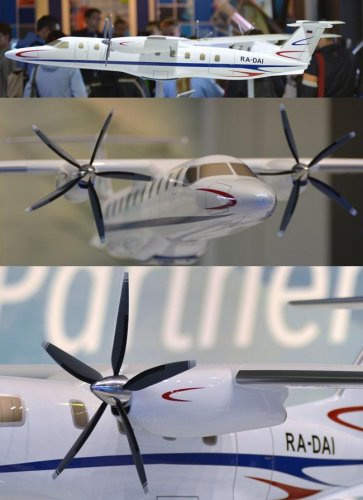

According to this source (PDF p21) the Ural Works of Civil Aviation (a subsidiary of Rostec, UWCA) and DAI signed an agreement on co-production and co-development of a family of light multipurpose planes for four, nine and 19 seats at the Le Bourget air show in June 2013. http://en.take-off.ru/pdf_to/to28.pdf

Regards Michael

The nine-seat LMS-9 powered by a pair of E-8 diesel engines rated at 440 hp each will have a maximum takeoff weight of 3,500 kg, while the takeoff weight of the 19-seat LMS-19 powered by a pair of 700-hp engines will equal 6,400 kg. The maximum cruising speed of both models will account for 440 km/h, and the flight altitude

will stand at 8,200 m. The LMS-9 burning 85 kg of fuel per hour will be able to fly fully-loaded out to 1,500 km, while the LMS-19 with a 140-kg/h fuel consumption out to 1,335 km. The price of the planes is estimated to be $2.5 million and $3.75 million respectively.

Regards Michael