- Joined

- 29 July 2009

- Messages

- 1,627

- Reaction score

- 1,942

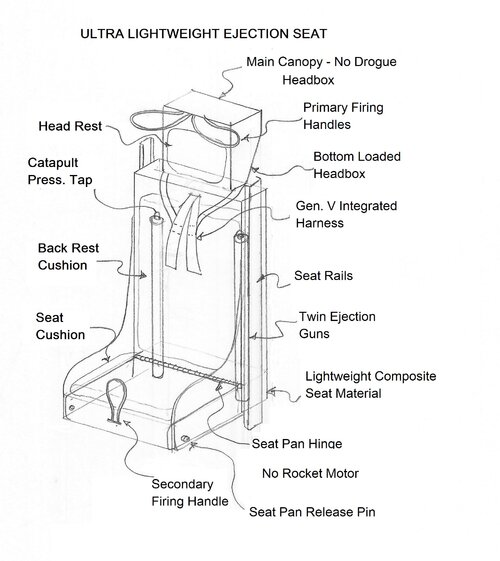

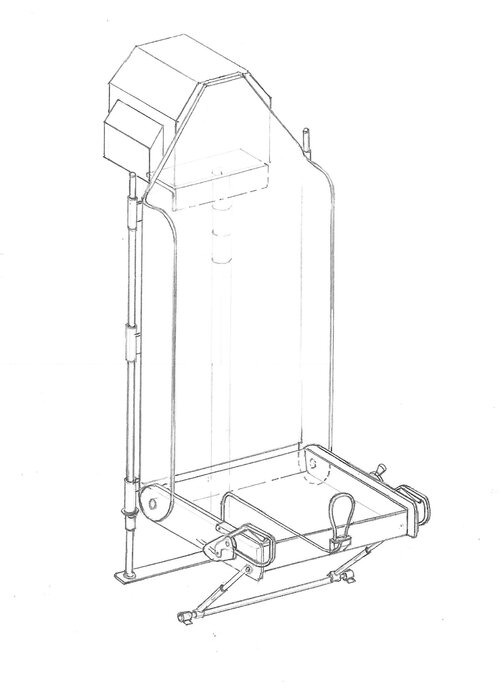

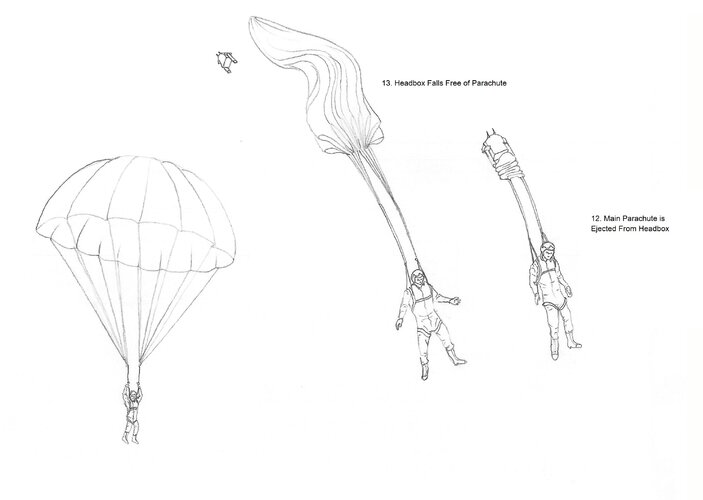

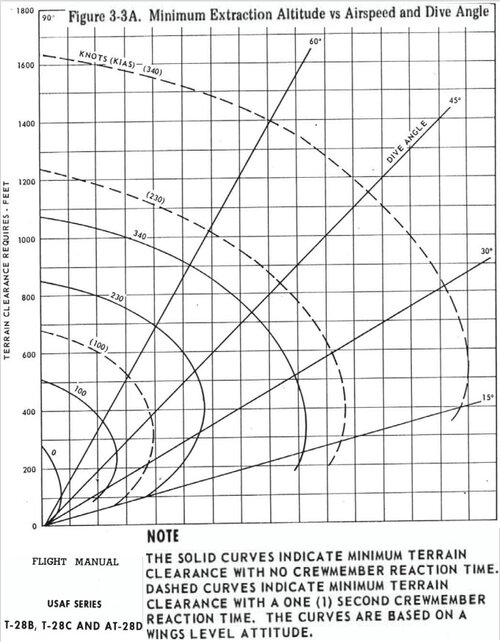

Over the last 60 years or so there have been a number of ejection seat designs for high speed military aircraft. These designs have eventually evolved enabling air crews to escape in zero-zero (i.e. zero airspeed-zero altitude) ejections conditions. The sophistication of some of the latest designs even have enabled air crew to eject upside down while descending toward the ground at low altitude. However, despite the proliferation of these systems in military aircraft there are very few ejection seats or systems that have been designed for light general aviation aircraft. The Cirrus aircraft company has developed their aircraft with Ballistic Recovery Systems (e.g. Cirrus and Cirrus Vision Jet aircraft) and other manufacturers have been incorporating BRS systems into their light aircraft designs. Unfortunately, most of these BRS designs have limited envelopes in which the pilot can safely deploy the BRS.

This thread is to discuss the possibility of a zero-zero or near-zero-zero ejection seat system for GA aircraft. Considering the weight and required sophistication of the design to eject, stabilize in a positive attitude and trajectory, and deploy a parachute or other decelerating device. The nearest design that I can find to the concept is the Russian NPP Zvezda SKS-94. https://russianpatents.com/patent/254/2540133.html

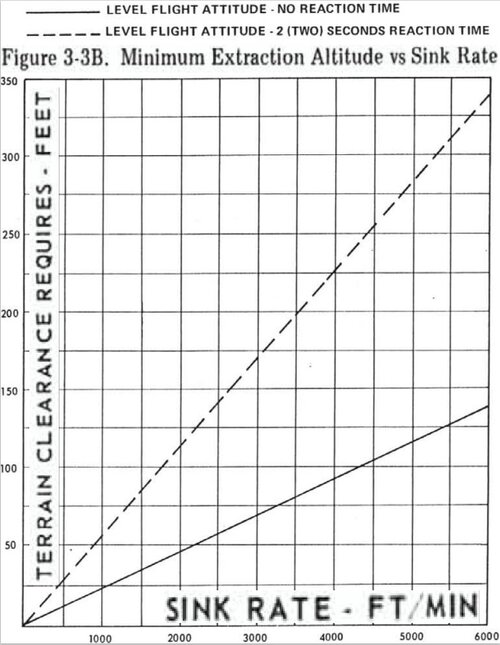

It can extract the pilot within 0.3 seconds as low as 33 feet altitude and costs $35,000 (1998 dollars). In 2015 Zvezda developed a pole system, which dates back many years to WWII and a compressed air version experimented with by Martin Baker.

This thread is to discuss the possibility of a zero-zero or near-zero-zero ejection seat system for GA aircraft. Considering the weight and required sophistication of the design to eject, stabilize in a positive attitude and trajectory, and deploy a parachute or other decelerating device. The nearest design that I can find to the concept is the Russian NPP Zvezda SKS-94. https://russianpatents.com/patent/254/2540133.html

It can extract the pilot within 0.3 seconds as low as 33 feet altitude and costs $35,000 (1998 dollars). In 2015 Zvezda developed a pole system, which dates back many years to WWII and a compressed air version experimented with by Martin Baker.

Attachments

Last edited: