I thought it would be time for a new design challenge, the around the world plane from pole to pole or westwards against the jet streams or anything other more difficult than that what the voyager has done before…

Before I come out with a design proposal, I will explain my idea of the flight profile. Of course, this is an idealized idea and reality can and will disturb it (weather, traffic, etc.). So, I will explain how it would work in an ideal world. It is clear, that this super long range aircraft will have a drastically changing total mass during the flight. For simplicity reasons, I declare the mass ratio 1 as the mass which allows for flying at an optimal angle of attack with max efficiency power at sea level. The starting mass could possibly be a bit higher (flying behind the power curve) and is set to 1.1. The fuel will be empty (a small reserve should be kept) at a mass ratio of 0.2 (might be overly optimistic…). For maximum efficiency, the plane should always fly with the best angle of attack and for most of the time with constant engine power. Of course, the engine should run in the point of best efficiency, except in the first part of the flight (mass ratio >1) where we allow it to run with a slightly higher rpm to reach more power.

Below a mass ratio of 1, the plane will become faster and to keep the optimum angle of attack, the ratio of lift and thrust must be kept constant. With a constant engine power, the plane must fly higher and become faster. If the mass ratio is down to 0.5, the plane will fly in 1/8 of the air density with twice the speed and half the mass, compared to mass ratio 1. The lift is:

L=C*2²*1/density

So with V2 = 2* V1 and density 2 = 1/8 * density 1 =>

L2 = ½ L1

Since we fly with a constant angle of attack, the drag is proportional to the lift

Fd2 = ½ Fd1

Thrust power:

P2=Fd2*V2 = Fd2*V1 = P1

So we see, the power can be kept constant with a declining mass ratio. It is clear, that the design should be able to fly quite slow (250 – 300 km/h) at sea level (mass ratio 1) and needs to climb really high (16500 m for a mass ratio of 0.5). With two stage turbocharging, we could even fly higher, so we continue with this up to a mass ratio of let’s say 0.4. With that mass ratio we reached the maximum height and speed (Mach number limitations) and need to change our strategy. In the next flight phase we continue to fly with a constant angle of attack, but we will reduce speed and engine power while maintaining the height. To ease calculations, we will do so, until we reach a mass ratio of 0.2. Let’s check how it works out for this point:

We will need only half the lift and lift is proportional to the square of the speed, so:

V3=1/2² *V2

With a constant angle off attack, thrust force is proportional to the lift, so it is also down to

Fd3 = 1/2 Fd2

The required thrust power will be:

P3 = P2 * Fd3* V3 = 0,039 * P2

This relatively low engine power will reduce efficiency, but to be honest, a mass ratio of 0.2 would be very low and probably unrealistic, I choosed it mainly because to simplify the diagrams.

The last part of the flight will be a powerless glide with the best angle of attack until we reach the landing side.

I made a diagram with the mass ratio vs. air density, this might be a bit unusual, but it allows to use straight lines instead of complex curves which would be required if the altitude would be used.

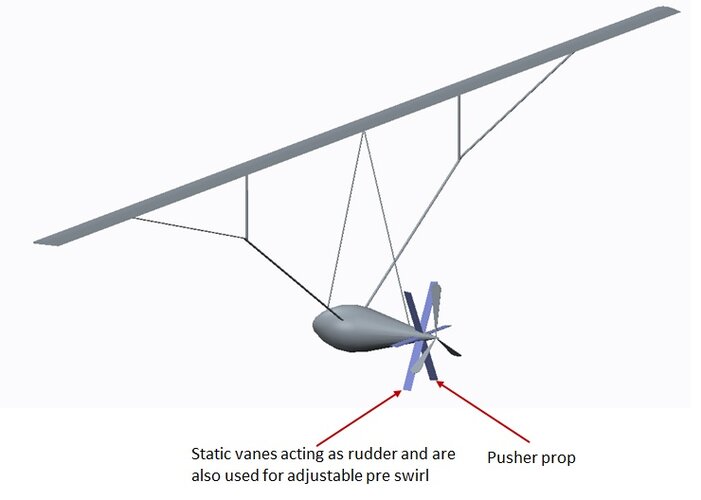

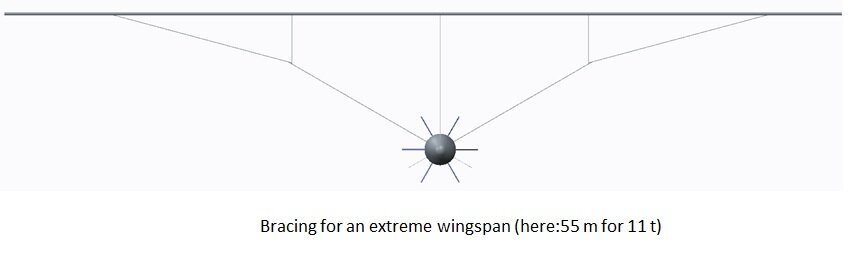

I would like to see design proposals for such a plane and will contribute something by myself….

Before I come out with a design proposal, I will explain my idea of the flight profile. Of course, this is an idealized idea and reality can and will disturb it (weather, traffic, etc.). So, I will explain how it would work in an ideal world. It is clear, that this super long range aircraft will have a drastically changing total mass during the flight. For simplicity reasons, I declare the mass ratio 1 as the mass which allows for flying at an optimal angle of attack with max efficiency power at sea level. The starting mass could possibly be a bit higher (flying behind the power curve) and is set to 1.1. The fuel will be empty (a small reserve should be kept) at a mass ratio of 0.2 (might be overly optimistic…). For maximum efficiency, the plane should always fly with the best angle of attack and for most of the time with constant engine power. Of course, the engine should run in the point of best efficiency, except in the first part of the flight (mass ratio >1) where we allow it to run with a slightly higher rpm to reach more power.

Below a mass ratio of 1, the plane will become faster and to keep the optimum angle of attack, the ratio of lift and thrust must be kept constant. With a constant engine power, the plane must fly higher and become faster. If the mass ratio is down to 0.5, the plane will fly in 1/8 of the air density with twice the speed and half the mass, compared to mass ratio 1. The lift is:

L=C*2²*1/density

So with V2 = 2* V1 and density 2 = 1/8 * density 1 =>

L2 = ½ L1

Since we fly with a constant angle of attack, the drag is proportional to the lift

Fd2 = ½ Fd1

Thrust power:

P2=Fd2*V2 = Fd2*V1 = P1

So we see, the power can be kept constant with a declining mass ratio. It is clear, that the design should be able to fly quite slow (250 – 300 km/h) at sea level (mass ratio 1) and needs to climb really high (16500 m for a mass ratio of 0.5). With two stage turbocharging, we could even fly higher, so we continue with this up to a mass ratio of let’s say 0.4. With that mass ratio we reached the maximum height and speed (Mach number limitations) and need to change our strategy. In the next flight phase we continue to fly with a constant angle of attack, but we will reduce speed and engine power while maintaining the height. To ease calculations, we will do so, until we reach a mass ratio of 0.2. Let’s check how it works out for this point:

We will need only half the lift and lift is proportional to the square of the speed, so:

V3=1/2² *V2

With a constant angle off attack, thrust force is proportional to the lift, so it is also down to

Fd3 = 1/2 Fd2

The required thrust power will be:

P3 = P2 * Fd3* V3 = 0,039 * P2

This relatively low engine power will reduce efficiency, but to be honest, a mass ratio of 0.2 would be very low and probably unrealistic, I choosed it mainly because to simplify the diagrams.

The last part of the flight will be a powerless glide with the best angle of attack until we reach the landing side.

I made a diagram with the mass ratio vs. air density, this might be a bit unusual, but it allows to use straight lines instead of complex curves which would be required if the altitude would be used.

I would like to see design proposals for such a plane and will contribute something by myself….

Attachments

Last edited: