- Joined

- 25 June 2009

- Messages

- 14,138

- Reaction score

- 4,325

Flying the Cabri G2 Guimbal

by Georgina Hunter-Jones

Pics by Alan Norris

Bruno Guimbal, like Frank Robinson, was an engineer working in the helicopter field, in his case for Eurocopter, when he had his dream of a small light piston helicopter. Like Robinson he brought this idea to his employer and like Robinson he found that his idea did not fit with the employer’s schedule. However, unlike Robinson’s case, but perhaps

learning from it, Eurocopter agreed to give Guimbal a lot of support, including the use of their research facilities and test rig. Guimbal took full advantage of this generosity. His first prototype was produced in 1992, but that got no further and he returned to development, finally bringing out the current G2 in 2007. Since 2007 he has sold forty helicopters, which between them have flown 14,000 hours.

Differences from other light helicopters currently in service include the main structure, which is made of carbon fibre with only a few uses of metal, such as the fire-wall, the rotor hub, the engine, the fenestron tail and the skids. This use of composites makes the helicopter light as well as strong, avoids corrosion and allows parts to be ‘on condition’ rather than time-lifed.

The rotor-hub is an aluminium alloy with magnesium forging for greater strength, and is surrounded by a rugged monofilament fibreglass winding ‘safety belt’ that will hold the rotor hub together even if it cracks in flight. The manufacturer says that this safety belt has been tested by deliberately fracturing the head, and then subjecting it to 700 hours at 1.5 times the full design loading. The safety belt extends the whole way up the blades to the tip weights, which it holds in place. As the blades are also carbon fibre they are light and have tip weights to keep the inertia high and to improve the tip-plane path. The main rotor has three blades with a high inertia system. This was designed to avoid the problems encountered in the R22 of a low inertia teetering-head system. The G2 head has elastrometric bearings and dampers and has used the Eurocopter example of the star flex technology in the head.

The G2 is the only piston engine helicopter with a fenestron tail. In this case it is a seven bladed fenestron, with a 9x gearing with the main rotor. Because the fenestron blades are almost completely flat the blades move very fast and increase the aerodynamic efficiency.

While it is not surprising that a light helicopter with Eurocopter influence has a shrouded tail rotor Guimbal enthusiasts talk of the clear advantages including its quietness; safety

in a public environment and the reduced likelihood of damage from the shrouded tail blades. However, on the downside, it is less powerful than the normal tail rotor and has a different usage range that is not linear.

Many parts of the Cabri G2 are made by outside contractors using moulds created by Guimbal. This includes the fenestron tail, which is made in two pieces and joined together in the factory.

(...)

SPECIFICATIONS

General characteristics

Crew: 2 (Removable controls for left seat)

Engine: 180 hp (134 kW) Lycoming O-360 piston engine

derated to 145 hp (108 kW)

Average fuel burn: 38 litres an hour

Fuel capacity: 170 litres

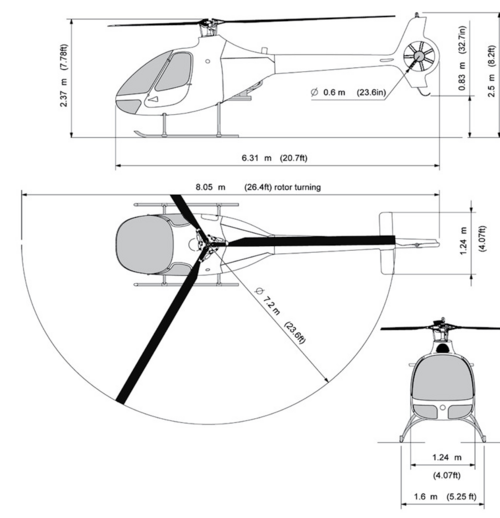

Length: 6.31 m (20 ft 8 in)

Main rotor diameter: 7.2 m (23 ft 7 in)

Width: 1.24 m (4 ft 1 in)

Height: 2.37 m (7 ft 9 in)

Gross weight: 700 kg (1543 lb)

Typical empty weight: 420 kg (926 lbs)

Performance

Maximum speed: 185 km/h (115 mph)

Cruising speed: 166 km/h (104 mph)

VNE Power on: 130 kts @ sea level

Range: 800 km (431 Nautical miles)

Endurance: 5.8 hours @ 55 knots

Service ceiling: 3963 m (13,000 ft)

Last edited: