Here More Links from NTSR

Cost Studies of Multipurpose Large Launch Vehicles:

Volume One: Summary

http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19690030191_1969030191.pdf

Volume Two: Half size (MLLV) Conceptual Design

http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19690030192_1969030192.pdf

Volume Three: Resource Implication

http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19690030193_1969030193.pdf

Volume Four: Baseline AMLLV Cost

Volume Five: Baseline MLLV Cost

Volume Six: Cost implications of Vehicle Size

http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19690030194_1969030194.pdf

Volume Seven: Advanced Technology Implication

http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19690030195_1969030195.pdf

Volume Eight: uncassified Appendices

http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19700001226_1970001226.pdf

Volume Nine: Propulsion Data and Trajectories (Classifed Appendices)

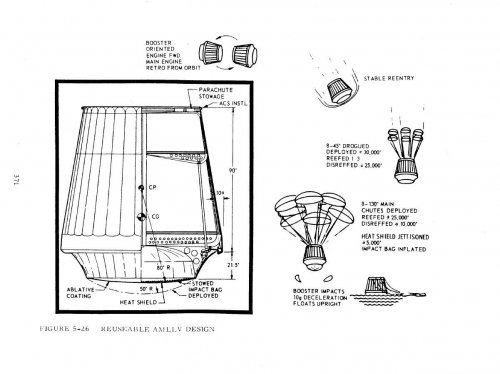

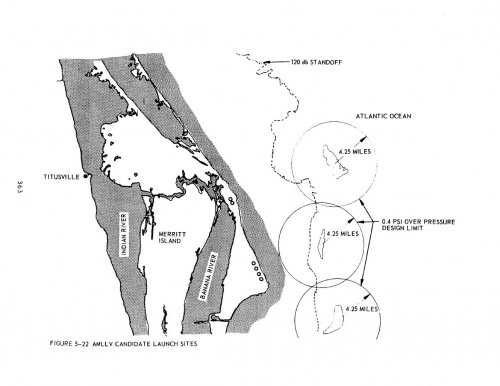

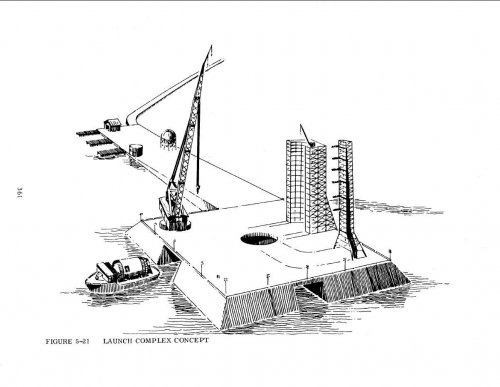

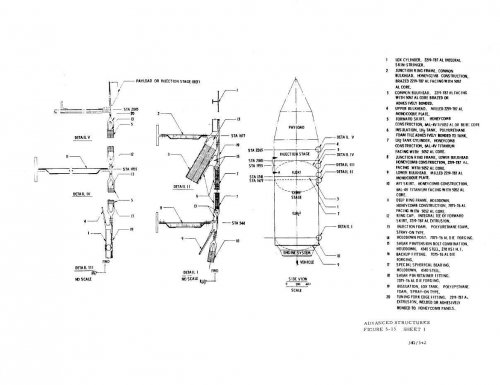

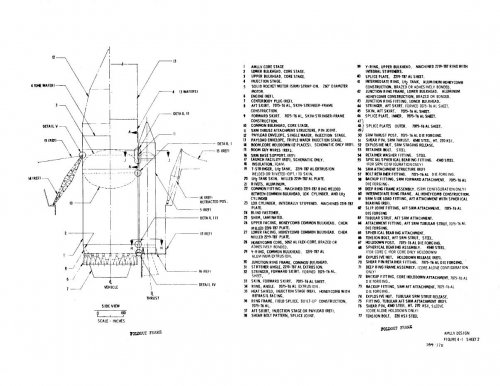

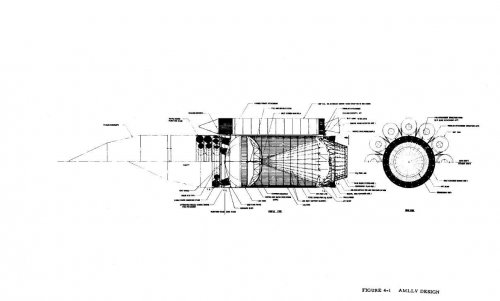

Study of advanced multipurpose large launch vehicles:

http://ntrs.nasa.gov/archive/nasa/casi.ntrs.nasa.gov/19750069565_1975069565.pdf

also (Parts of Volume Five?)

Baseline MLLV costs - Get ready or A costs, book A Final report - Document ID: 19700001823

Baseline MLLV costs - Developmental or B costs, book B Final report - Document ID: 19700001824

Baseline MLLV costs - Operational or C costs, book C Final report - Document ID: 19700001825

Nik said:

Wow, that's a BIG booger !!

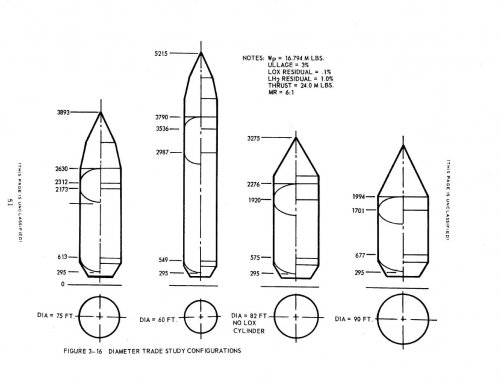

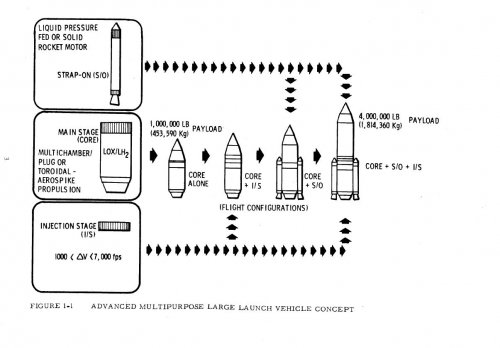

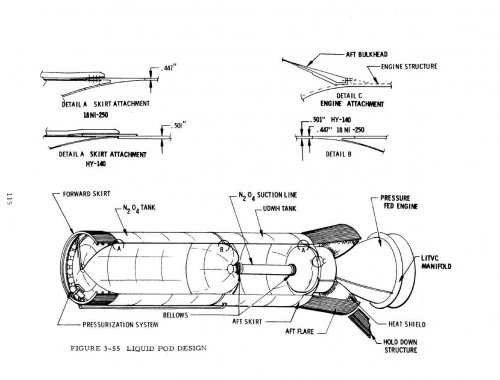

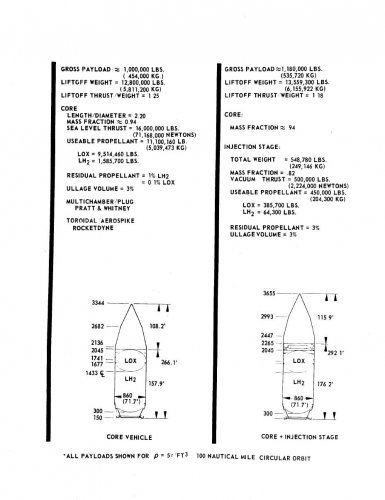

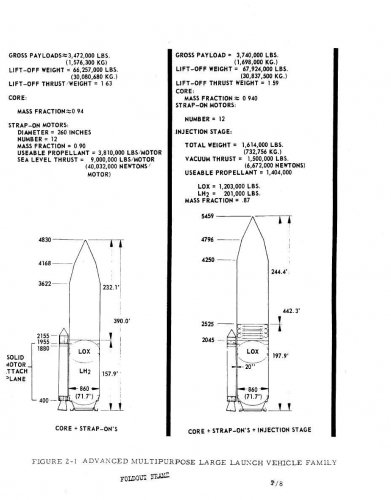

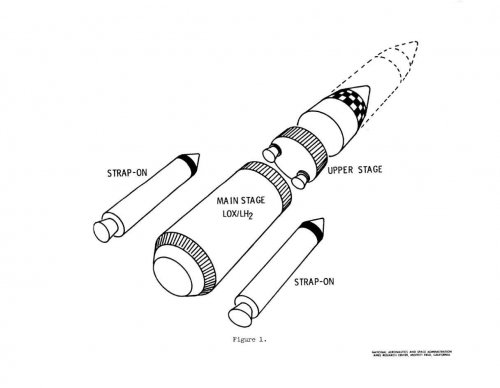

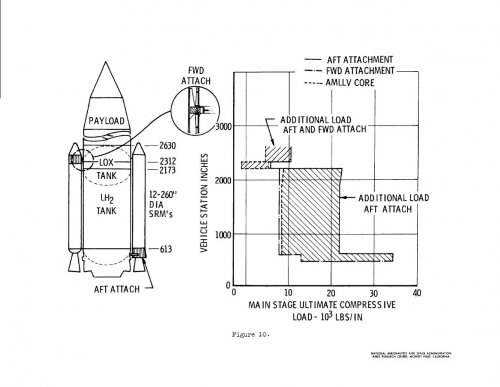

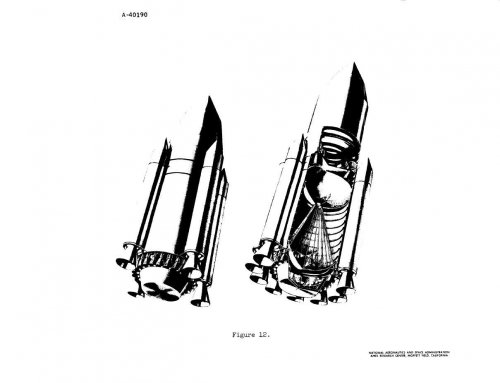

there studied two size: A(dvance)MLLV and half size MLLV

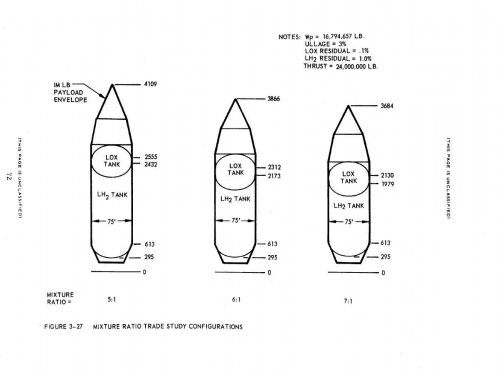

all Payload in 100 n.m. 185,2 km orbit

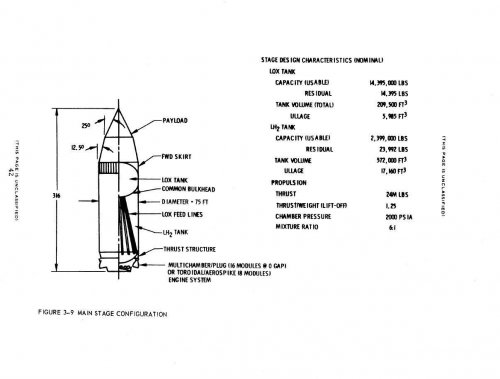

AMLLV standard size: 266 ft x 71.6 ft ø / 81 meter x 21,8 meter ø

1.0 million lbs / 453592,0 kg

MLLV standard size: 220 ft x 56.6 ft ø / 67 meter x 17,2 meter ø

471000 lbs / 213642 kg