From February 2004, BMT Defence Systems unveiled the concept of the SSGT (Ship Submersible Gas Turbine):

http://forum.keypublishing.co.uk/archive/index.php?t-28700.html

BMT white paper on the SSGT:

http://www.bmtdsl.co.uk/BMT/bmt_media/bmt_media/33/2007-09-26Concept-SSGTDataSheet.pdf

BMT Defence Services Ltd unveiled its concept for a high mobility submarine at the Pacific 2004 maritime exhibition in Sydney, Australia, at the start of February.

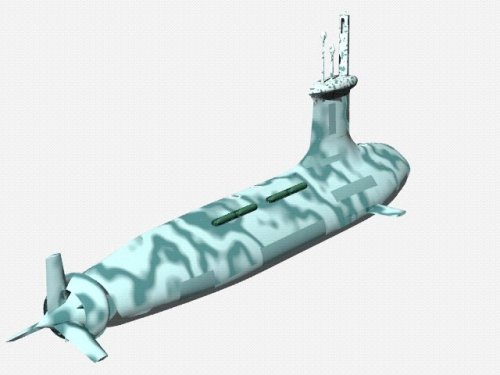

A model of the SSGT (Ship Submersible Gas Turbine) was displayed on the BMT Defence Services stand at the show, attracting interest from naval delegations and defence sector professionals from many Pacific Rim regions and countries including Australia and New Zealand; south-east Asia, Canada and the USA during the four day event that began on 3rd February 2004.

Marketing Director for BMT Defence Services, John Davis, explained the key benefits of the design to those viewing the disruptively-patterned submarine model: “SSGT is designed to provide effective mobility approaching that of an SSN without the financial and political costs of ownership associated with having a nuclear reactor onboard”.

Conceived by design engineers at BMT Defence Services in Bath, UK, the SSGT sees the first serious proposal for using gas turbines in a conventional submarine. Though gas turbines can be very compact they are voracious consumers of air and submarine designers have to date been unable to arrange sufficient volumes of air to feed gas turbines buried inside the hull of a submarine.

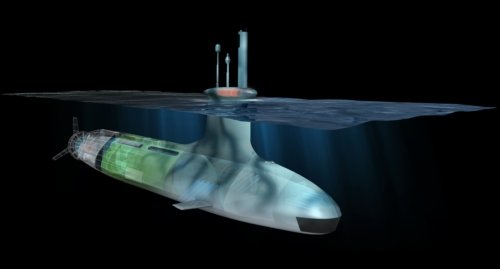

The innovation proposed by BMT Defence Services, in consultation with gas turbine specialists Rolls Royce, is to locate two independent gas turbine-electric alternator sets in individual containments located in a bulb at the top of the submarine fin where they can draw sufficient air through an 8m tall induction mast. When operating on gas turbines, the submarine runs semi-submerged, with just the gas turbine bulb above the sea surface. In this mode, SSGT is able to travel up to 6,000 nautical miles at 20 knots, far in excess of the capability of a conventional diesel-electric submarine.

The SSGT design trades off tactical covertness of the submarine against strategic mobility on the assumption that the submarine will meet few, if any, threats during transit. Once in-theatre, SSGT shuts down its gas turbines, dives and can operate fully covertly for up to 25 days in an Air Independent Propulsion mode (AIP). A mixture of fuel cells and advanced ZEBRA batteries provide power for systems and permit submerged operations up to 10 knots and short tactical sprints at 30 knots respectively. Kerosene is used to fuel the gas turbines and (via reformers) the fuel cells thus giving deep flexibility between transit and in theatre operations. Liquid oxygen is stored to enable the fuel cells to operate when the boat is submerged. SSGT may also run its fuel cells at the surface taking air using a conventional snort mast. In this way the boat may be more covert whilst in transit and preserve the stored liquid oxygen to maximise discretion in theatre.

Well resourced in onboard power, SSGT supports a highly capable and comprehensive combat suite including chin, fin and flank sonar arrays, six heavyweight torpedo tubes, eight vertical launch missile tubes and stowage for four large unmanned underwater vehicles (UUV) or swimmer delivery vehicles (SDV). Accommodation for up to 12 special forces personnel and a six-man lock-in lock-out chamber complete a flexible design capable of undertaking a range of high and low level missions.

http://forum.keypublishing.co.uk/archive/index.php?t-28700.html

BMT white paper on the SSGT:

http://www.bmtdsl.co.uk/BMT/bmt_media/bmt_media/33/2007-09-26Concept-SSGTDataSheet.pdf

![FC150, 2005-10-14, SSGT - Fin + Platform Montage [(c) BMT].jpg](/data/attachments/27/27103-c9f8a4f26973a8aa3d366ba884e4ba36.jpg)