E class is a bit of an outlier, most container ships have 2 shafts afaik

The E class are actually a bit of a weird transitional state, designed before the 2008-2009 financial crisis (and rising environmental awareness) led to a reduced emphasis on speed and increased emphasis on efficiency, but still trying to make economies. The single shaft was part of that. Newer container liners return to two, relatively lightly loaded, screws because they can be optimised for minimal fuel consumption at relatively modest speeds.

Older ships - and the preceding Maersk B class are an extreme example - had two shafts for very high speed. In the case of the B class, 34 MW (46,000hp) per shaft for a sustained 29 knots, and ran trials at 34 knots.

He's absolutely right: power requirement are not directly related to weight but to surface.

This only applies to frictional resistance, which is one of two principal components of resistance for a ship. The other is wavemaking resistance, which is not a function of surface area, but of hullform and displacement. At very low speeds, or away from a free surface, wavemaking is negligible, which is why nuclear submarines look the way they do and have atrocious surfaced performance.

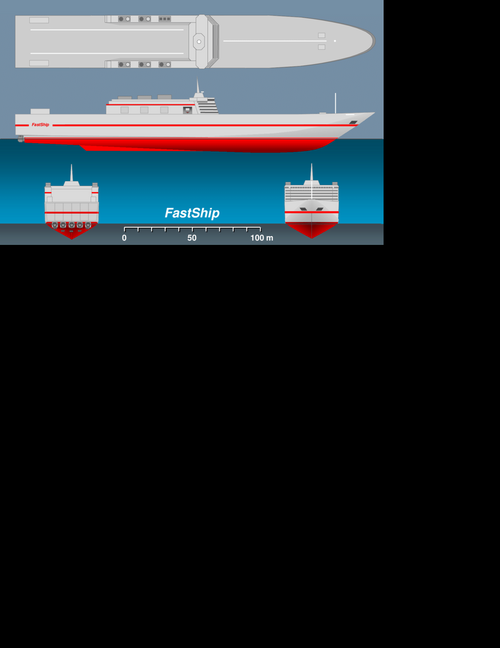

Wavemaking does weird things with peaks and troughs of resistance - troughs corresponding to integer numbers of wavelengths along the ship, troughs at the half-integers. Once the wave length equals the ship length at a Froude number of 0.4, wavemaking starts growing at an eyewatering rate, sometimes as quickly as the

sixth power of speed. If you really want, you can push on to a Froude number of 0.5 or so, which is the 'hump speed' where the bow is at the crest of a wave and the stern is in the trough. Above that speed, you move into the semi-displacement, and ultimately fully planing, regimes, where fundamentally different hullforms are needed.

Interestingly, though, if you scale up a displacement hull, it gets longer, so the Froude number goes down. This means that a larger ship will usually have less wavemaking resistance per tonne of displacement, often falling off much quicker than frictional resistance. A similar phenomenon is why it's sometimes possible to lengthen a ship, increasing the displacement, and yet get the same or higher speed from the same powerplant.