- Joined

- 1 April 2006

- Messages

- 11,375

- Reaction score

- 10,209

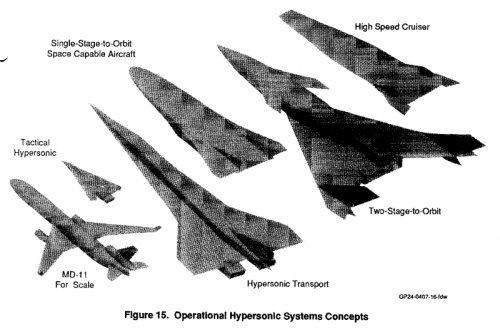

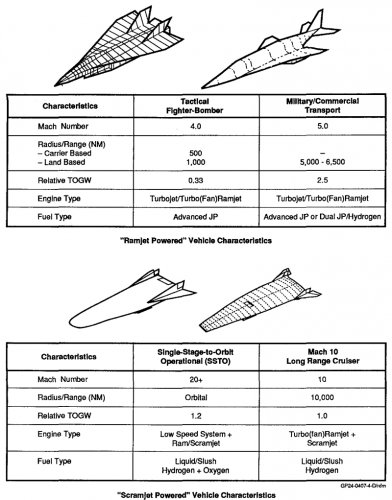

Excerpt and drawings from some Boeing AIAA papers. DF stays for Dual Fuel

______________________________________________

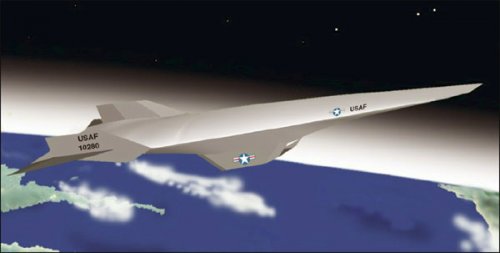

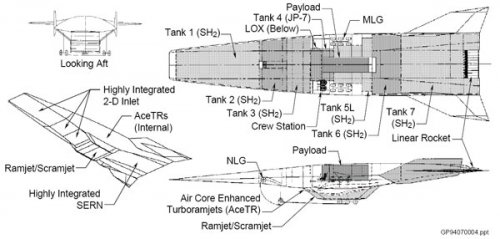

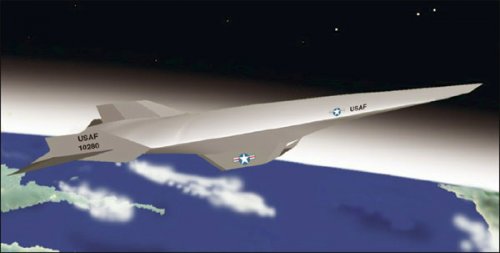

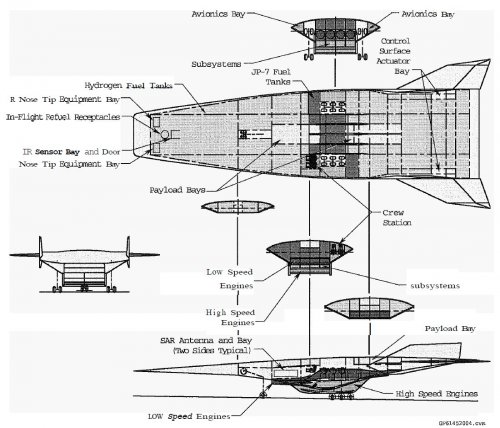

The Mach 10 aircraft concept which became

the vision for Hyper-X, features a lifting body configuration with an over-andunder

turbine based combination cycle (TBCC) engine

system. For this system, four hydrocarbon-fueled, lowspeed

turbo-ramjet engines are integrated inside the

vehicle, directly above three high-speed, hydrogenfueled

scramjet engines. This 61 m-long aircraft was

sized for an operating radius of 8500 nautical miles

(nm). The low-speed engines are used initially for takeoff

and acceleration to Mach 4. The high-speed engines

are then used for acceleration to and cruise at Mach 10.

Following the high-speed cruise mission, the aircraft

returns to base sub-sonically using the low-speed

engines. During return, it is refueled using KC-10

tanker aircraft. (!) (All of the engine design and

performance information, employed in the definition of

this Mach 10 aircraft, was provided by Pratt &

Whitney.)

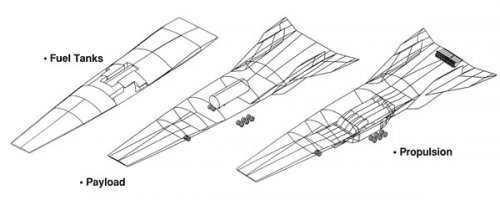

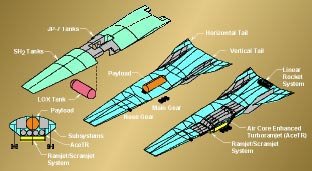

The airframe structure, materials, thermal protection

system (TPS), vehicle management system, and

subsystems for the Mach 10 aircraft are described in

References 2,3 and 4. The fuselage is based on a cold,

integral structure, in which the cryogenic hydrogen

tanks are integral with the airframe. The tanks/fuselage

are built-up with graphite-epoxy frames and skins, and

the skins are covered with TPS. The TPS consists of

Tailorable Advanced Blanket Insulation (TABI) on the

upper surface of the aircraft (similar to the Shuttle

Orbiter) and Internal Multi-Screen Insulation (IMI) on

the lower surface. IMI is a developmental TPS, which

consists of carbon/silicon-carbide (C/SIC) outer panels,

intermediate ceramic screens, separated by ceramic

spacers, and an internal layer of advanced polyimide

foam (APF). The intermediate ceramic screens are

coated with a noble metal to reduce their emissivity.

The wings and vertical tails are constructed of titanium

matrix composite material and have zirconium diboride

leading edges. The nose consists of a hydrogen-cooled

NARloy-Z structure.

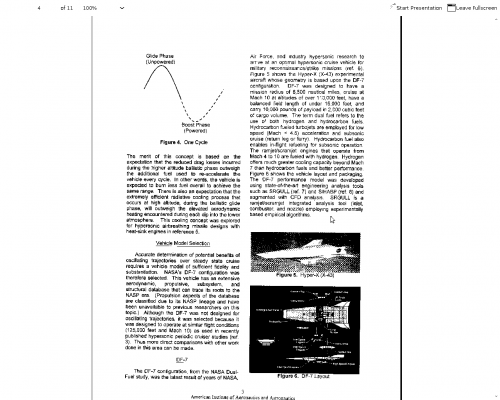

With this aircraft concept serving as a vision vehicle,

the Hyper-X (X-43A) was conceived to demonstrate, in

flight, the performance of an airframe-integrated,

scramjet powered vehicle. Also, Hyper-X II (which

later evolved into the X-43B) was conceived as a

follow-on step to demonstrate a larger, more flightweight,

scramjet powered aircraft. These flight

research vehicles became part of NASA’s Advanced

Space Transportation Program (ASTP), and a third

vehicle, the X-43C, was added to serve as an

intermediate step between the X-43A and X-43B. In

addition, a large-scale flight demonstration vehicle is

being considered as part of the ASTP hypersonics

investment strategy. This vehicle could lead to a future

hypersonic aircraft or 3rd generation, air-breathing,

reusable launch vehicle.

______________________________________________

The Mach 10 aircraft concept which became

the vision for Hyper-X, features a lifting body configuration with an over-andunder

turbine based combination cycle (TBCC) engine

system. For this system, four hydrocarbon-fueled, lowspeed

turbo-ramjet engines are integrated inside the

vehicle, directly above three high-speed, hydrogenfueled

scramjet engines. This 61 m-long aircraft was

sized for an operating radius of 8500 nautical miles

(nm). The low-speed engines are used initially for takeoff

and acceleration to Mach 4. The high-speed engines

are then used for acceleration to and cruise at Mach 10.

Following the high-speed cruise mission, the aircraft

returns to base sub-sonically using the low-speed

engines. During return, it is refueled using KC-10

tanker aircraft. (!) (All of the engine design and

performance information, employed in the definition of

this Mach 10 aircraft, was provided by Pratt &

Whitney.)

The airframe structure, materials, thermal protection

system (TPS), vehicle management system, and

subsystems for the Mach 10 aircraft are described in

References 2,3 and 4. The fuselage is based on a cold,

integral structure, in which the cryogenic hydrogen

tanks are integral with the airframe. The tanks/fuselage

are built-up with graphite-epoxy frames and skins, and

the skins are covered with TPS. The TPS consists of

Tailorable Advanced Blanket Insulation (TABI) on the

upper surface of the aircraft (similar to the Shuttle

Orbiter) and Internal Multi-Screen Insulation (IMI) on

the lower surface. IMI is a developmental TPS, which

consists of carbon/silicon-carbide (C/SIC) outer panels,

intermediate ceramic screens, separated by ceramic

spacers, and an internal layer of advanced polyimide

foam (APF). The intermediate ceramic screens are

coated with a noble metal to reduce their emissivity.

The wings and vertical tails are constructed of titanium

matrix composite material and have zirconium diboride

leading edges. The nose consists of a hydrogen-cooled

NARloy-Z structure.

With this aircraft concept serving as a vision vehicle,

the Hyper-X (X-43A) was conceived to demonstrate, in

flight, the performance of an airframe-integrated,

scramjet powered vehicle. Also, Hyper-X II (which

later evolved into the X-43B) was conceived as a

follow-on step to demonstrate a larger, more flightweight,

scramjet powered aircraft. These flight

research vehicles became part of NASA’s Advanced

Space Transportation Program (ASTP), and a third

vehicle, the X-43C, was added to serve as an

intermediate step between the X-43A and X-43B. In

addition, a large-scale flight demonstration vehicle is

being considered as part of the ASTP hypersonics

investment strategy. This vehicle could lead to a future

hypersonic aircraft or 3rd generation, air-breathing,

reusable launch vehicle.