Since writing the original post I have been provided with a RRHT article which may be regarded as 'definitive'

Proteus Icing problem… an article for RRHT by Bryan Williams

The Problem

In the mid-1950s the Bristol Britannia, the first large, long range, four turbo-prop engine powered airliner was entering into service. Subsequent to the development flying, route proving and initial operation, an unexpected meteorological problem was encountered. In temperate regions, particularly over the North Atlantic, no problems had occurred. However on routes through tropical regions to South Africa and the Far East, when flying in cloud at the normal cruising flight level of 20-25,000ft., icing conditions were encountered. Ice built up in the engine intakes, then periodically broke off and passed through an engine, momentarily extinguishing the combustion flames and causing a ‘bump’ which although not dangerous, was uncomfortable for passengers and unacceptable to the airline. The problem was seriously delaying entry into full service, and there was an urgent requirement to understand and fix the problem.

Investigations

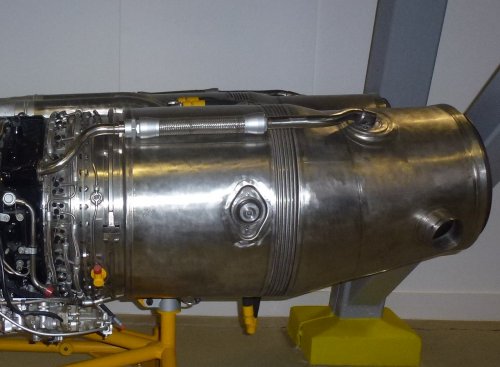

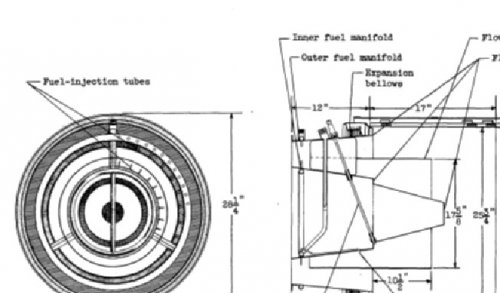

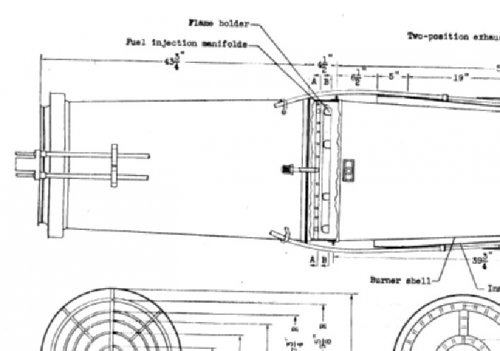

The Britannia used the Bristol Proteus III turbo-prop engine; this was developed from the earlier Mk II version, which had been designed for the Brabazon II and Princess aircraft. To achieve a minimum length, the engine had reverse flow which was retained in the Mk III version. The airflow after entering the forward facing intake, passed along the outside of the engine, and then turned approximately 180° to a forward direction before entering the compressor. It was found that under certain tropical conditions, ice accumulated on the outer radius of this 180° bend, then periodically broke off and entered the engine. Earlier flight tests had included those on an Ambassador aircraft which was re-engined with the Proteus III and fitted with equipment to spray water into the intake under icing conditions. A very early version of closed circuit TV was also fitted which speeded up the test programme as events could be seen immediately during flight, rather than waiting for the processing of film.

This work showed no problem in the inlet duct, only icing on the compressor inlet guide vanes which was dealt with by the anti-icing system fitted. It had also been considered that heat from the core of the reverse flow engines would eliminate any possible icing in the intake duct. In order to understand the problem, a wide ranging investigation involving Bristol Aero Engines Ltd, the Royal Aircraft Establishment Farnborough (RAE) and the Meteorological Office was undertaken.

Flight tests in Central Africa, based at Entebbe in Uganda with the CCTV on an engine confirmed the build-up and shedding of ice. Other instruments were fitted in an attempt to gain data on ambient moisture levels. Within tropical cumulo-nimbus clouds at the flight level, there appeared to be three possible cloud conditions which could be the cause:

1. A super-cooled water droplet cloud with air at above 0°C.

2. An ice crystal cloud well below 0°C (‘dry icing’).

3. A cloud with a mixture of free water and ice crystals, slightly below 0°C (‘mixed icing’).

The first condition could be considered as the conventional low level icing problem. Super-cooled water droplets freeze on impact with an aircraft, giving glazed icing on wings, engine cowling leading edges and propellers and various methods have been developed to remove the ice or prevent the build-up, typically by the application of heat to the surfaces.

During operation in the ‘dry icing’ condition, some of the ice crystals seemed to partially liquefy on the warmer walls of the intake. This enabled the crystals to adhere to the walls, other crystals then coalesced on this base until a piece of ice broke off and was ingested. This process was observed in flight and was also reproduced in an altitude test facility. A similar process in an accelerated form took place in the ‘mixed icing’ condition. Free water moistened the intake surfaces, giving a base for ice crystal adhesion. It appeared that this only occurred when the ambient temperature was somewhat below 0°C. At around 0°C a combination of slightly super-cooled water droplets and ice crystals did not adhere. As glazed ice deposits formed, they were eroded by ice crystals.

The principle variables in ‘dry icing’ and ‘mixed icing’ were total water concentration and air temperature.

Data from instrumentation on the flight tests and altitude test facility runs, showed engine incident rate increasing with concentration levels in ice crystal clouds at various temperature levels. Concentration effects in ‘mixed icing’ conditions were also demonstrated. In this case there were two variables. With low levels of free water it was found that up to a certain level of ice content there was no build-up. As the concentration of ice crystals increased, accumulations of ice growing increasingly large and shedding less frequently were formed. If the free water content was increased at a given ice content, the deposits washed away before reaching any great size.

The ‘mixed icing’ condition was most critical in producing engine incidents, so one aim was to establish if there was a critical value of total water concentration.

Determination of this was difficult, it was not possible to simulate in ground tests and no flight instruments were available to measure ice crystal content in the presence of liquid water. Data from RAE suggested that total water concentrations within the intake of less than 2-4 grms/cu.metre, of which a large proportion was in the form of ice crystals would not cause problems. It was also considered that there could be some ‘enrichment’ in the intake due to crystals and droplets being drawn into the intake. This factor was difficult to assess, but may have been as high as 2 or 3, so implying that the critical concentration in the free air was possibly between 1 and 2 grms/cu.metre at the 20-25,000 ft. flight level. Changes in temperature produced differing results in the ‘dry’ and ‘mixed’ icing conditions. In the former case, increased temperature seemed to increase engine disturbance, probably due to warmer intake surfaces on which ice crystals impacted, melted and coalesced more readily. The latter condition showed a less marked effect, probably due to some water being present on the surfaces over the narrow temperature range involved.

The investigation then attempted to establish the frequency of climatic conditions which produced high concentrations. Unfortunately there was little data then available on the free water content of clouds. It was thought that an estimate could be obtained by analysing rates of rainfall data at points along the aircraft routes, as the rate of rainfall might be related to cloud water content. However data on rainfall rates, as opposed to the total amount of rainfall in a period, was not available in these tropical regions.

The Solution

During the summer and autumn of 1957 there was a period of intense activity to find a solution to this problem.

In addition to ground tests of complete engines, other basic work was undertaken. For example, the compressor alone was run on the electrically driven 3000HP compressor test rig to measure effects of ice ingestion. The best simulation of an incident was obtained by dropping bags of chipped potatoes into the compressor inlet while it was run at speed!

A two dimensional aerodynamic model of the 180°C inlet bend was also made in wood and Perspex. Air was blown through the model and a spray of table salt granules injected into the stream from a pressurised tank, together with a very fine spray of water. This gave a good simulation of ice buildup

(N.B. it had to be Cerebos salt, as for some reason Saxa would not stick!). Various changes to the duct shape were made including weirs and fences on the surface. None of these made any significant difference.

Eventually, a solution was found on this rig. A narrow slot was formed on the outer radius of the bend and a jet of air blown through it which increased the velocity of the boundary layer in that area. After some trial and error an optimum position was obtained. It was then found possible to fit ducting to the engine nacelles to allow warm air to be bled from the compressor to feed similar slots when icing conditions occurred, (they became known as ‘B Skin Jets’). It of course did cause a small reduction in engine performance when operating. Further flight tests in Central Africa and later from Singapore and Darwin confirmed the effectiveness of this method. In addition, glow plug equipment was installed in the combustion system to give an automatic relight, should an event still occur.

Conclusions

These problems over 50 years ago showed the result of an unexpected meteorological condition on the operation of an airliner. It only occurred in tropical conditions where high water contents existed in clouds at the flight level. Eventually the Britannia proved a very efficient and reliable airliner for the time, being in service with several airlines and the RAF for a number of years. This was particularly shown on the North Atlantic routes in the late 1950s. The long range version was the only aircraft then capable of flying consistently westbound from London to New York in virtually all weather conditions without a refuelling stop. The Israeli airline El Al was particularly innovative in developing ‘pressure pattern’ flying, by diverging from great circle flight paths in accordance with forecast upper winds and also increasing altitude as fuel was burnt. They were able to fly eastbound, New York -Tel Aviv, 6,100 miles, without a stop. A serious result of the various delays entering into full service was that sales of the aircraft were limited, as airlines preferred to wait for the pure jets then being developed, (e.g. the Boeing 707). Ironically, after all the work, delays and insistence of the users that the problem must be completely solved, it is believed that the equipment was little used. Aircraft captains, wherever possible, changed course or altitude to avoid flying through tropical cumulo-nimbus cells to minimise general air turbulence and give maximum comfort to their passengers.

Also this picture [from

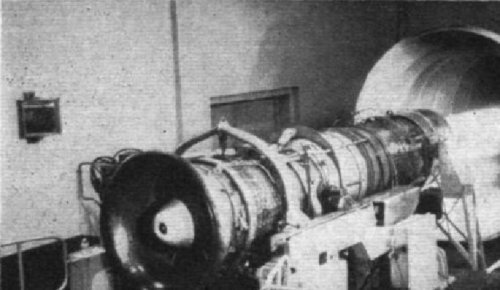

here] shows the trial in Africa.